eAxle: Improving the commute through Suzhou

Cao Mengyi takes us on a tour through the Chinese city of Suzhou, the Venice of the East

Known as “the Venice of the East,” the verdant Suzhou is where Cao Mengyi works. She drives her Ora Good Cat there every morning. Her electric car is powered by the eAxle from Bosch.

An enjoyed start to the day

Day dawns in Suzhou, China. Life in the city, that is mostly covered in water, is already pulsating at eight in the morning. The sun shines on the enchanting Chinese gardens with lakes, pavilions, and rock formations, on numerous water villages with bridges and canals, and on Cao Mengyi, who makes her way to work in the administrative department in a local design institute. It’s not just the spectacular surroundings that make her work commute to the Design Institute easier. It’s been a few months now that she has been driving her new car, powered by Bosch’s eAxle. “Ever since, I’ve really enjoyed the daily commute,” proclaims Cao Mengyi.

It feels so easy and flexible to drive. I really enjoy my daily commute to work.

China is the frontrunner for electric cars

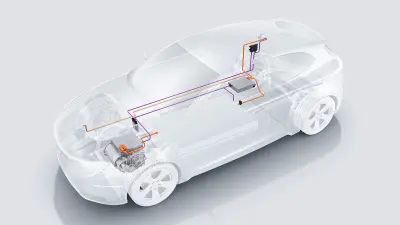

Cao Mengyi didn’t just choose the Ora Good Cat as her daily companion because of its good looks. Instead, she is convinced that the all-electric drive of the small Chinese car is the future — and she wants to sit in the driver’s seat, so to speak. Cao Mengyi likes her choice of the small electric car because it means she is doing something to reduce CO₂. “It makes me feel good every morning knowing that I can help protect the environment.” Cao Mengyi’s motivation fits the trend in society today. Around one in four new passenger cars in China is powered by an electric battery. More electric cars were sold here in 2021 and 2022 than everywhere else in the world combined. The market share for electric vehicles reached almost 28 percent in 2022. The future is electric, and Cao Mengyi wants to be part of it. She can only feel, not see, the innovativeness of Bosch’s eAxle in her vehicle. The latest generation of the innovative solution for the electric powertrain of battery electric vehicles not only reduces the previous complexity of the electric powertrain, it makes the powertrain less expensive, more compact, and more efficient.

Up to six percent

The increase in range that the use of silicon carbide-based power semiconductors in the eAxle could offer

The perfect 3-in-1 electric powertrain

With its high efficiency and scalability, the 3-in-1 electric powertrain solution opens the doors to the future of mobility. The eAxle’s modular design means that complexity, which would otherwise delay development, is reduced and it allows power, torque, and installation space to be flexibly and individually adapted to the respective vehicle concept. It can then be used in many areas of electromobility.

The high scalability of the eAxle (50–300 kW) and the option of different voltage levels (400/800 V) paired with the high flexibility in terms of delivery also help respond to individual customer requirements and make the eAxle ready for all vehicle types.

Enormous performance potential thanks to silicon carbide semiconductors

With future generations of the Ora Good Cat, people who use their cars a lot, like Cao Mengyi, will also benefit from the use of silicon carbide semiconductors in the eAxle. The innovative material allows the available energy to be used particularly efficiently. Silicon carbide plays out these advantages particularly in energy-intensive applications such as electromobility. Customers are now able to drive significantly further on one battery charge — around six percent on average compared with their silicon counterparts. Bosch uses silicon carbide chips, which will be installed in cars worldwide, in its eAxle. And Suzhou, an hour west of Shanghai, is no exception.

What’s behind the power of the eAxle

Lots of commuting, little time charging

Cao Mengyi glides past the gardens and lakes in the morning, while listening to the radio and enjoying the confident laid-backness that her new car exudes. The half-hour drive through the city of twelve million inhabitants leads to work, but it also leads to a relaxed feeling resulting from a silent powertrain and flexible and pleasantly dynamic handling.