What exactly does an Industry 4.0 technician do?

Five questions for Tobias Richter

Connected industry technician is quite a mouthful for a job title — especially as the job is about simplification: Tobias Richter makes life easier for people working in manufacturing at Bosch. Here’s how it works.

Mr. Richter, what does your job actually involve?

My responsibilities include all production and maintenance-related aspects of connected industry in the plant; several team members help me with that. The most important thing we do is to think in terms of the big picture rather than of separate departments. I get together with people from the maintenance department to work out how we can make various processes in the plant even better by tapping into the opportunities offered by digitalization. So my job is about supplying the right people with the right technologies, which I help deploy in the plant.

You work with the “Nexeed MSS”. What exactly is that?

Nexeed MSS stands for Maintenance Support System. It is a connected industry solution designed to make life easier for our maintenance technicians. Bosch developed it itself. In the past, our repair people had to do a lot of walking: first to the workshop to pick up a repair order, then to the faulty machine to check out what was wrong, then to the warehouse to get the spare parts they needed, then back to the workshop again to browse through the manuals. Nexeed MSS saves them a lot of this effort — and when you consider the up to 80,000 machine faults that crop up in a large plant every year, you can see why that makes such good sense!

“Whether we’re focusing on traditional manufacturing or the digital realm, we work together to ensure the products that come off the line are top quality.”

How does Nexeed MSS work in practice?

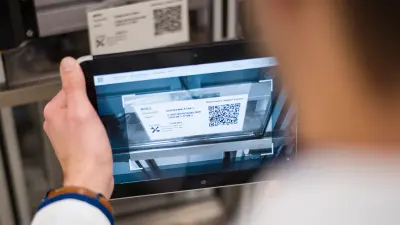

Let’s say there’s a faulty sensor in a machine. The manufacturing operative simply uses a tablet to take a photograph of the defective part and send the pictures to the maintenance people along with an error report. Technicians can bring the right part with them the first time, thus sparing themselves the trip to and from

the supply area, which can mean around ten minutes saved if the plant is a large one. If the maintenance technicians need more information from the machine operating manual, they don’t have to go to the filing cabinet to get it. All they have to do is scan the QR code on the machine and call up the manual on their tablet.

What does a digital expert like you do when the working day is over?

I’ve pretty much turned one of my personal interests into a full-time job. I use tablets and smartphones all the time at home, and sometimes I build my own computers. But I do take occasional breaks from it all. I read historical novels, do odd jobs around the house, and in the winter, go skiing with my wife. In general I love playing sports, jogging, and working out. I used to play a lot of handball. In fact, I was on a team with my twin brother, who actually works at the same Bosch plant as me, in the robotics department.

“Having an affinity for digitalization isn’t a question of age — it’s more a matter of attitude.”

Will Bosch need more software experts in its manufacturing operations in the future?

We’ll increasingly need experts who are well versed in the digital aspects of manufacturing. And Bosch is already busy training such specialists. At our plant, we try to bring apprentices up to speed by providing concrete examples of how I4.0 can be applied. We also encourage people to obtain further qualifications in this area. In my experience, having an affinity for digitalization isn’t a question of age — it’s more a matter of attitude.

Profile

Tobias Richter

Connected industry expert at the Homburg plant in Germany

My job is to make life easier for people working in manufacturing at Bosch. Connected industry is the tool I use to achieve that.

Tobias Richter studied mechanical engineering at the University of Kaiserslautern, where he majored in mechatronics. In 2012, he joined the Bosch plant in Homburg as a trainee and was appointed as a maintenance planner 18 months later. In early 2016 he took on the role of manager in the smart maintenance project. Together with his team, his responsibilities now include connected industry maintenance projects, including the introduction of Nexeed MSS.

Summary

Industry 4.0 experts such as Tobias Richter are driving forward technology and digitalization at manufacturing plants. To achieve that, they work closely together with manufacturing specialists and with Industry 4.0 developers. Nexeed MSS makes maintenance and manufacturing more efficient and, both at Bosch and other companies, can be deployed in plants anywhere in the world.