Research projects on the use of AI in manufacturing

AI in manufacturing: Bosch Research is working on the factory of the future

Shaping the future: AI will fundamentally change manufacturing processes

The fourth industrial revolution is in full swing. At its core is the intelligent networking of machines and processes in factories with the help of information and communication technology. According to a study by the auditing company PwC, 91 percent of all industrial companies already invest in digital factories. However, only six percent of them can claim that their operations are already fully digitized. Bosch Research wants to increase this rate. We are focusing on researching the use of AI in production processes and developing solutions based on it – for digital factories with artificial intelligence logistics and automation robotics. Models based on deep learning can reduce production times, increase flexibility in manufacturing, and improve product quality. As a result, production processes become more efficient overall, costs are reduced.

Smart factories: Invented for Life

Bosch has set itself the goal of becoming a world-leading AIoT company. By 2025, every Bosch product should either be AI-enabled or manufactured with the help of AI. In doing so, our AIoT cycle and its clear focus on user benefits always guide our path.

AI in manufacturing combines big data with production experience

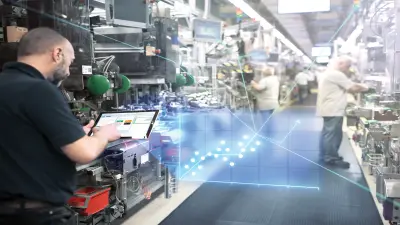

The key factor for smart factories and Industry 4.0 is the data that arise from the use of intelligent and networked products, the interaction between humans and machines and machines with one another. At Bosch we have about 240 plants around the world in which numerous networked production systems are in use. These generate an enormous amount of data that require the use of efficient data processing methods. The Bosch manufacturing and logistics platform helps to access and structure this data. By using AI methods, we gain useful and - compared to human analyzes - objective knowledge very quickly. At the same time, we have accumulated a considerable amount of knowledge and models for many manufacturing processes over the past few decades. Our ability to combine these two elements - data and knowledge of production processes - in what are known as hybrid models - is a great advantage when it comes to implementing AI solutions for manufacturing and logistics.

A variety of new possibilities

The use of the huge amounts of data analyzed in real time with the help of AI will make it possible to manufacture products faster and with higher quality, bringing artificial intelligence production and logistics to the next level. Models based on deep learning are able to detect and avoid even those errors that humans or classical systems have difficulty perceiving. But predictive analytics will also be able to optimize production in the future in other ways:

- AI will enable companies to more strongly individualize their products without much additional process-related effort.

- AI will help robotics find its way into areas where it was previously inconceivable. With the help of AI, the learning effort is reduced, the robot's vision is improved and thus transfer learning is made possible in the first place.

Speed and quality for smart factories

Analyzing data from manufacturing control systems has been a very time-consuming process. With the help of AI, we can not only analyze the data faster, but also send the insights drawn from it directly to dashboards that inform operators when something is wrong. In the future, these insights can also be used to give the machine's control system new instructions, such as adjusting parameters for example. In the end, this might lead to AI-based closed-loop production systems, which are self-regulating or self-optimizing. A list of possible root causes for problem resolution is provided right along with it.

In other words, the use of AI allows to speed up and to optimize production processes overall. It helps improving quality by greatly reducing scrap. In addition, with the help of AI, the utilization of machines and equipment can be planned more efficiently. Most importantly, customer satisfaction increases in the end.

Bosch Research and BCAI:

Combined know-how

In the development of AI-supported solutions, Bosch Research works hand in hand with the Bosch Center of Artificial Intelligence (BCAI). Bosch Research implements pilot use cases in Bosch's various production facilities, develops methodologies to efficiently combine process knowledge and AI, and provides tools to scale and roll out insights generated from the pilots across the company.

BCAI, in turn, brings together experts in AI research, applied AI, data science, and software development to develop scalable AI software systems and solutions that directly benefit end users.

Research in AI of in manufacturing

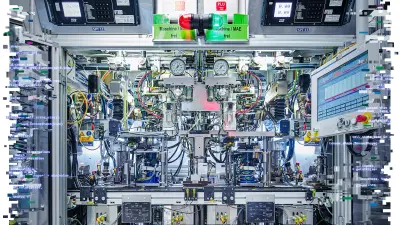

MAS - Manufacturing Analysis Solutions

In this area, Bosch is developing scalable AI and analytics solutions to detect anomalies and malfunctions in the manufacturing process at an early stage and determine the root causes. These solutions process millions of data points from various sources.

AOI - Automated Optical Inspection

Behind this are advanced deep learning approaches designed to improve optical inspection processes for goods produced by Bosch.

Robotic assembly

Here, we are developing novel perception and control algorithms that enable skilled/efficient processing of parts and tools. The goal is to be able to automate even highly complex assembly processes.

Process Optimization

In this field we focus on the development of algorithms that automatically adapt machines to the respective production and processing requirements.