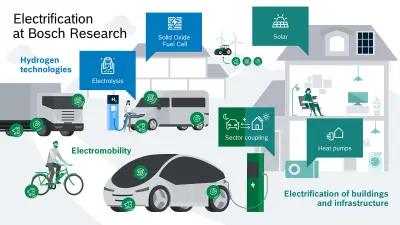

Energy transition, electrification, and electrolysis — research for greater environmental and climate action

To mark World Environment Day, Bosch Research provides an insight into its research activities in the field of climate and environmental action.

June 5 is “World Environment Day”. A day that once again raises awareness of the importance of environmental and climate action for a sustainably good life and the future of our planet. Bosch Research is aware of this task and provides technical answers to ecological questions. The focus of many of the research activities at Bosch Research is on improving lives through technologically smart solutions that protect the environment and resources. So, we research and develop technologies which contribute to continuously reducing Bosch's product carbon footprint and work on concepts of circular economy.

On the road with electric drives

In the field of electromobility, Bosch Research is researching and developing the technological foundations for the transformation of all types of vehicles: from e-bikes, motorcycles, cars, and trucks to off-road vehicles such as excavators, at all stages of electromobility value creation. This includes semiconductor components, power electronics, electric drives, and overall systems such as the Bosch eAxle. Important questions are e.g.: will copper remain the electrical conductor of the future? Or: can rare earth magnets be replaced by more sustainable and readily available materials? Bosch Research is working intensively in cooperation with leading research institutions worldwide.

From water to hydrogen with the smart electrolysis module

In the electrolysis process, hydrogen is produced from water. Due to the technology's significant importance for climate protection, Bosch founded a new business field in 2022 and plans to invest up to 500 million euros in the technology in the coming years. The electrolysis stack, where the electrochemical process takes place, is the most crucial component. Bosch initially focused on developing a 1.25 MW PEM (Proton Exchange Membrane) electrolysis stack. At the same time, a “smart electrolysis module” is being developed. It combines the PEM electrolysis stack with a control unit, power electronics and sensors. Bosch Research has been a pioneer in this field since 2012 and continuously incorporates its long-standing expertise into product development.

On the road with hydrogen

While electrolysis produces hydrogen from water, stationary or mobile fuel cells convert hydrogen back into electricity. Fuel cells can be used in various areas, such as in industry, buildings as a replacement for natural gas or oil heating, or in commercial vehicles. Mobility based on fuel cell drives promises long ranges and short refueling times due to the high energy density of hydrogen. The current development focus is on achieving series production readiness of the electrolysis stack with Proton Exchange Membrane (PEM) technology. Bosch Research is also enhancing the efficiency of fuel cell systems and seeking solutions for more cost-effective and readily available materials.

Decentralized energy for buildings

To provide buildings with decentralized energy, Bosch Research relies on stationary fuel cell systems. The Solid Oxide Fuel Cell (SOFC) technology is designed for future operation with hydrogen and is climate-neutral when using green hydrogen — i.e. hydrogen produced with renewable electricity. The SOFC system is currently in the pilot phase and can already operate with natural gas or biomethane, emitting about two-thirds less CO₂ compared to electricity production in coal-fired power plants1. It achieves an electrical efficiency of around 60 percent at the beginning of life. When waste heat is additionally utilized an overall efficiency of up to 90 percent can be reached.

CO₂-free heating with electric energy also plays a crucial role in decarbonizing buildings. In Germany, buildings account for around 30 percent of greenhouse gas emissions2, particularly through heating. Currently, heat pumps in combination with a photovoltaic system are considered a suitable way to drive the energy transition in the heating cellar. Bosch has been offering heat pumps for single and multi-family homes for many years. In the latest generation of heat pumps, the Bosch Home Comfort division uses natural refrigerants and operates particularly quietly. Research also contributes to “smarter” heat pump systems through virtual development, control technology, and machine learning. Compact designs of the refrigeration cycle allow heat pumps to be used in buildings with limited space.

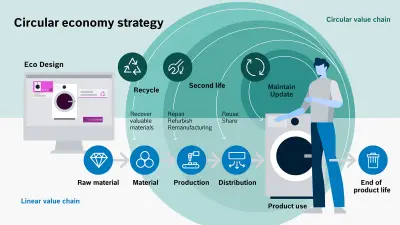

Thinking things through with “Circular economy”

Due to increasing resource scarcity, it is important to use resources efficiently and sustainably. Therefore, Bosch Research is involved in researching and implementing the concepts of Circular Economy. We consider the entire life cycle of a product and strive for its sustainability in every production and usage step, up to a second life. One lever of Circular Economy is to use materials that are sustainable from the start, e.g. by using materials with a certain recyclate share. However, turning supposedly waste materials into sophisticated industrial technology has been challenging. Researchers at Bosch Research are currently working on using recycled plastic materials in products, which has already succeeded in a project turning starter batteries into ultrasonic sensors.

Thinking things new: When reducing is no longer enough

One way to deal with unavoidable CO₂ emissions would be to remove CO₂ from the atmosphere. Similar to a vacuum cleaner, “Direct Air Capture” sucks in large amounts of air, which is then filtered within a collector in several steps and subsequently released with a significantly lower CO₂ content. Therefore, Bosch Research is intensively working on technologies to capture carbon dioxide from the ambient air and evaluating corresponding market entry scenarios.

With all these research projects, Bosch Research remains true to Bosch's self-conception: We develop technology for life — not only for today, but also for future generations.