The first Bosch power tool – a hair trimmer

A hair trimmer as the forerunner of the hammer drill, the angle grinder, and the cordless screwdriver? It is hard to believe at first, but that is in fact how the era of Bosch power tools began.

More than automotive

The story of Bosch power tools begins with a profound crisis in the European automotive industry. Sales had plummeted around 40 percent, forcing a number of Europe’s hundreds of small automakers into insolvency or to merge with others, such as Benz and Daimler.

As an automotive supplier, Bosch was also hit hard and had to take swift action to become less dependent on the automotive industry by offering new products that were both attractive and commercially successful.

It was none other than Robert Bosch himself who said to Hermann Steinhart, head of the design department, “Mr. Steinhart, we need other products to keep our production lines running!” Steinhart then showed Bosch a handy electric hair trimmer. Ernst Eisemann, founder of the company with the same name that Bosch had acquired several years prior, had brought him this device.

The inventor

Eisemann was an inventor who had designed and built the hair trimmer in his own workshop. It had a small electric motor in the handle to power its mechanism, which was a considerable improvement on the conventional hair trimmers with suspended motors and flexible shafts. However, Steinhart had criticized the device’s inadequate electrical fuse. After Bosch had seen the hair trimmer, he immediately tasked Steinhart with developing the experimental one-off into a product geared to the market. Resitex – a virtually indestructible plastic that the Bosch “isolith plant” at the Feuerbach location near Stuttgart manufactured – was used for the housing. In 1928, it was possible to present the new hair trimmer under the name Forfex to customers. The Bosch subsidiary Eisemann handled manufacturing and sales, although the motors came from Bosch.

First series launched

The only thing left to do now was convince barbers and hairdressers that it was better and more convenient to work with Forfex than conventional trimmers. To this end, Bosch representatives distributed a pilot series for free to hair salons across Germany. Within just a few months, word of the Forfex’s benefits had spread throughout the industry, winning people over with comfortable, fatigue-free use.

However, this is not the end of the story of the Forfex and its aftereffects, which can still be felt today. It could have been an episode in Bosch history or a small product niche for specific needs.

A new division

But the Forfex represents the beginning of a new division at Bosch – the current Power Tools division — which is well known for its green tools for DIY users and blue tools for professionals.

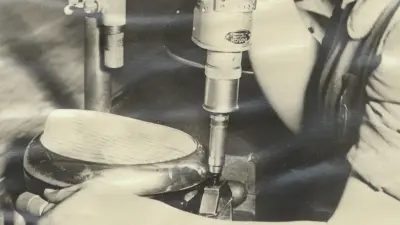

The basic design of the Forfex was the inspiration for the development of light power tools that Bosch began using in 1932 as grinders, drills, and screwdrivers in the production of diesel injection pumps — and then offered to customers outside the company after the trial phase. At the time, there were no compact power tools for production on the market that had an integrated motor.

Witnessing research

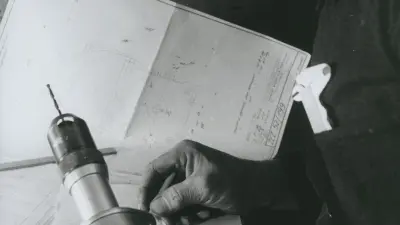

In order to transform the delicate product for hair salons into an indestructible metalworking tool, however, the Forfex had to undergo tough tests that an engineer back then later described as follows:

“We went to production and got a few [...] FORFEX motors wound for a 110 V alternating current, unscrewed the attachment to connect the motor to 220 V and measure its speed. At 220 V, the motor ran at approximately 13,000 rpm and functioned perfectly for a few minutes. Then it started to smell and that was it. [...] We varied the rotor diameter, the number and size of the slots, the number and diameter of the wires used for the armature, and the collector. After no more than about six weeks, we had a motor that, at idling speed, ran at approximately 16,000 revolutions with a power consumption of 30 watts (compared to 8-10 watts for the FORFEX motor) for over one hundred hours. We built the tool wanted in diesel injection pump production in Feuerbach, which had proved effective in testing [...].”

Author: Dietrich Kuhlgatz