Safe Braking

Start of developing Bosch's anti-lock braking system ABS

From 1969 on, Bosch had been working on an antilock system for motor vehicles. That was the beginning of the story leading to today's anti-lock braking system ABS.

At one time or another, almost every driver discovered that wheels lock under heavy braking, making the vehicle impossible to steer. The physical reality — that a wheel still rolling during braking requires a significantly shorter braking distance than a wheel that has locked, and helps keep a vehicle stable and steerable — was also already well known. In 1936, Bosch registered a patent for a “mechanism to prevent locking of the wheels of a motor vehicle.”

Despite considerable efforts, a breakthrough was not yet on the horizon: the antilock systems fell victim to the sluggishness of their mechanical controls and were unable to react quickly enough to the ultra-rapid change in conditions during braking.

The availability of semiconductor technology starting in the early 1960s set the stage for what was to come. Electronics made it possible to reduce or increase braking pressure at an appropriately rapid speed. In 1969, Bosch began in-house predevelopment on an anti-lock braking system.

-

Velocity sensors of an antilock system for passenger vehicles, 1969 -

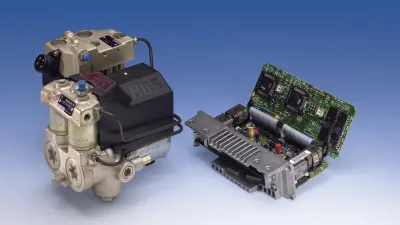

ABS 2 components (hydraulic modulator and control unit), 1978

The first production-ready ABS

At the time, Heidelberg-based Teldix GmbH had already been performing research on an antilock system for vehicles for five years and had developed a promising electronically controlled antilock braking system that could control all four wheels independently of each other. The system was met with great interest by the automotive industry, and preparations for mass production got underway. However, it turned out that the analog electronics available back then did not satisfy the safety requirements for a braking system. Extensive winter testing proved the ability of the ABS 1 system to function, but the electronics were not sufficiently durable.

After acquiring a 50 percent stake in Teldix in 1973, the main contribution made by Bosch was its development and manufacturing experience with electronic components, which were robust enough for use in vehicles. In 1975, Bosch took over full responsibility for ABS development and later bought up all the remaining Teldix shares. In 1978, ABS 2 was unveiled, Bosch’s first production-ready electronically controlled ABS.

A standard safety feature

The anti-lock braking system reliably stopped wheels from locking up under heavy braking and kept vehicles steerable, helping avoid uncontrolled skidding following emergency braking in many cases. From the start, the additional safety was undisputed. ABS 2 and its successors gradually became standard equipment in all vehicle segments.

In 2018, for example, Bosch launched the eBike ABS, the first production-ready ABS for e-bikes, based on the already established ABS for motorcycles. Bosch’s anti-lock brake systems have been helping guarantee safe braking for more than four decades.

Author: Bettina Simon