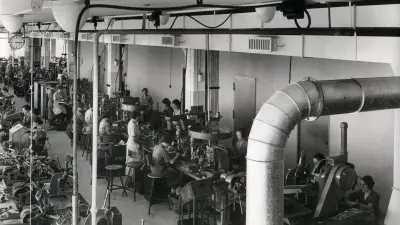

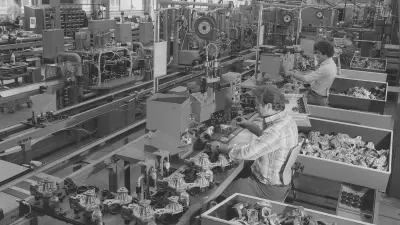

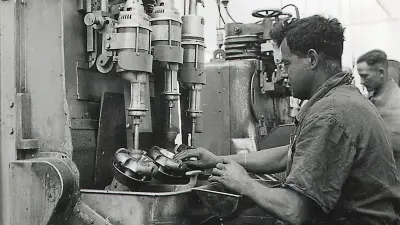

Robert Bosch’s first factory in Stuttgart

The early years in pictures

Robert Bosch set up his first factory amidst residential buildings in the center of Stuttgart in 1901. His plan was to start producing magneto ignition devices for automobiles there. But the factory quickly became too small to cope with the rapid rise in demand for Bosch ignition systems. Four years later, a second factory building was constructed next door. That was the end of the growth, Bosch thought at the time. Historical photos illustrate just how wrong he was. Within mere decades, Bosch expanded into an industrial enterprise that took up virtually an entire neighborhood. Known as the “Bosch-Areal,” the complex became a site where the company produced a wide range of automotive equipment. Not only did Robert Bosch place great value on having state-of-the-art facilities, he also ensured good working conditions for his workers.

Author: Vera Dendler