A clear view in any weather

The history of the Bosch windshield wiper

Driving in the rain, snow, and fog — nowadays, no one thinks twice about it, but in the early days of the automobile it was a real challenge. Many inventions of the 1910s and 1920s were aimed at making driving easier and helped the new means of transportation achieve a breakthrough. In 1926, Bosch launched the electric windshield wiper on the market, thus making an important contribution to greater safety in cars.

Difficulty driving in the rain

Both Max Rall, member of the Bosch board of management, and chief designer Hermann Steinhart were well acquainted with this unpleasant scenario: you’re out and about in your car, the weather’s great, but then rain clouds roll in. The initial light shower turns into steady rain and it starts getting dark. Driving home becomes an ordeal; you can’t see the road or anything else through the windshield. That’s why, at the end of 1923, Rall and Steinhart agreed to develop a windshield wiper. There were already some early models, but these varied widely and it was difficult at first to get a handle on all the possibilities.

Precursors

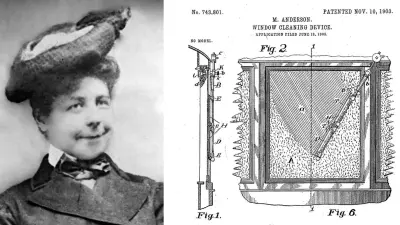

The first functional windshield wiper system was patented in the U.S. in 1903. It was invented by Mary Anderson after a visit to New York in winter, where she observed the efforts of a streetcar driver to maintain a clear view in icy rain. She then sketched a device consisting of a lever-operated arm with a rubber blade. The lever could be operated from inside the vehicle and allowed the arm to wipe back and forth across the windshield.

In addition to various hand-operated devices, windshield wipers of the following years operated electrically or by means of the vacuum in the engine’s intake tract. The one thing they all had in common was that they didn’t work very well.

Simple, reliable, compact

The engineers at Bosch set to work with the aim of developing a simple, reliable windshield wiper. They quickly determined the key parameters: the finished product shouldn’t be too large or too heavy, and it should be easy to attach to all types of vehicles. The wiper should clear a sufficiently large area and its movement should be as quiet and smooth as possible.

However, this supposedly simple task presented two particular challenges. First of all, the engineers needed to find the right type of rubber. Although soft material achieved good wiping results, it quickly became brittle. More robust types of rubber could be moved over the windshield only with a great deal of force and would have made the motors powering the wiper far too massive. The other challenge was wiping pressure. In the course of a wiping cycle, the pressure would change considerably depending on the position of the wiper arm and the condition of the windshield. To compensate for this, the engineers designed a spiral spring that pressed the wiper lever — with the rubber wiper blade in its metal mount — against the windshield as evenly as possible.

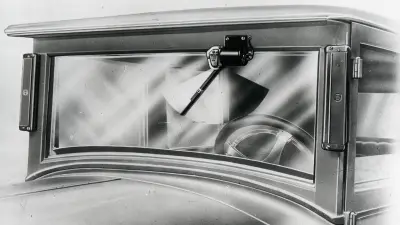

Three years later, it was ready: the Bosch product launched in 1926, and put an end to all weather problems and technical shortcomings. The windshield wiper was powered by a small electric motor via the car battery and thus worked regardless of whether the engine was running. Its power consumption had been kept to an absolute minimum, so that nothing stood in the way of long journeys in the rain. For even better visibility, a second wiper lever could be fitted to keep the passenger side free of rain and snow as well.

Successful large-scale production

The electric windshield wiper quickly became standard. The demand for wiper motors and wiper blades grew in parallel with the steadily rising number of vehicles. In the 1960s, Bosch greatly expanded its wiper production and invested in the further development of its products.

It started in 1959 with the “windshield washer.” The device was equipped with a pump that sprayed a rinsing agent onto the windshield, making it possible to quickly clean a dirty windshield while driving.

Innovative further development

Better visibility was also ensured by windshield wipers with “overlap.” That was the key to how the wiper blades of the new systems were able to clear a large area of the panoramic windows of the 1960s: the unwiped wedge in the center of the window slid far upward and enlarged the free field of vision. To prevent the two wiper arms from getting in each other’s way, they were alternately accelerated.

Interval switches, rear window wipers, rain sensors, new motor technologies, and numerous refinements to the wiper blades followed. In the 1990s, two different types of rubber were thermally bonded together for the first time in the Twin wiper blade. A wiping lip made of hard natural rubber was excellent at staying functional over the long term. The soft synthetic rubber backing proved to be particularly resistant to the temperature fluctuations of summer and winter and enabled smooth operation.

Spotlessly clean

From 1999 onward, the Aerotwin wiper blade, which was the first to do without multipart joints, ensured a more even distribution of contact pressure. Two pre bent spring strips pressed the rubber of the wiper blade against the windshield. This made it possible to significantly improve wiping quality, while the flatter design reduced wind noise. In subsequent generations, the rubber wiper blade was covered with an additional coating that made it more robust and allowed it to glide more easily over the windshield.

Barely noticed, but essential for a safe journey

Despite all the advances, the basic requirements for Bosch windshield wipers have remained the same since the first model in 1926: optimum wiping results with quiet operation. Indispensable in everyday driving, the windshield wiper does its job without any fanfare — because the less it is noticed, the better it provides a clear view.

Author: Bettina Simon