Washing dishes with Bosch

Less effort, lower water and power consumption

Washing dishes by hand is one of the least popular household chores: wash first, rinse with clean water if necessary, then dry — and be careful with those delicate dishes! The journey from the first dishwashing machines to today’s efficient household helpers was a long one.

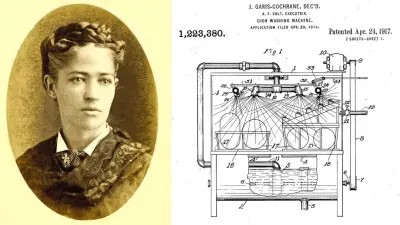

Award-winning invention

In 1893, a world’s fair was held in Chicago. Among the many technical innovations on show was an appliance that made washing up easier in restaurants and pavilions at the exhibition: U.S. inventor Josephine Cochrane’s dishwashers. This device was also honored at the final award ceremony: the machine won in the category of best mechanical design, durability, and suitability for purpose.

Patented in 1886, this dishwasher was the first appliance of its kind fit for everyday use. Given how family heirlooms suffered repeated damage when they were washed up by hand in the evening, Cochrane developed a mechanical dishwashing process that was gentle on the dishes and at the same time eased the burden on housewives. Her dishwasher consisted of a copper boiler with wire baskets into which the dirty dishes were placed. Nozzles sprayed pressurized hot water and soap suds onto the dish racks. These moved on a rotating wheel through the boiler – initially hand-cranked, later motorized — until they were clean.

The art of getting the ratio right

With her design, Cochrane had already addressed the main points that are still decisive for a dishwasher today: the way the water is sprayed, the water temperature, the duration of the washing program, and the chemical effect of the detergent. Bringing these factors into balance is the art of the “dishwashing technician.”

Although Cochrane’s dishwasher already did a satisfactory job, it would be several decades before this novel home help became established. The appliances were expensive, making them worthwhile only in kitchens that used a lot of dishes, for example in hotels and hospitals. There were also some technical problems to solve. The machines were often not watertight, didn’t cleanly thoroughly enough, or broke the dishes. It wasn’t until the 1950s that the development of dishwashers made decisive progress, first in the United States and then in Europe.

Development work in the dishwashing lab

Bosch first started working on the household dishwasher in 1960. In March 1961, a dedicated department was set up under the umbrella of the home appliance development department. The work began with many trials. A dishwashing laboratory was set up so that the dishwashing and drying processes could be carried out in a reproducible manner. The task was to thoroughly wash away, again and again, food components such as starch, fats, proteins, but also fibrous substances such as salad and vegetables or colorants such as ketchup and tea – regardless of whether they were previously cooked or fried, and air dried or hard baked onto the surface. Afterwards, all the dishes should come out of the machine dry, whatever material they were made from. But there were also many tasks to be solved on the design side: new housings and containers had to be developed and built, as well as automatic dispensers, water softening systems, dish racks, control units, heaters, and pumps. The plastic and rubber parts in particular suffered from switching between detergent solution, acidic rinse aid, and salts from the water softener. With the help of the plastics development department, it was possible to find suitable materials; these colleagues also managed to take time away from testing thermosetting plastics for distributor caps to define test methods for resistance to detergent and rinse solutions.

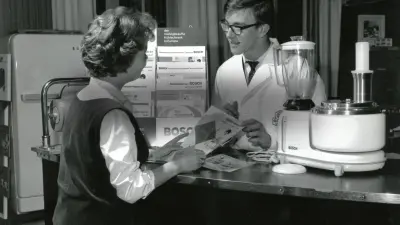

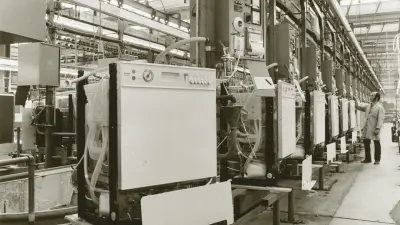

The dishwasher goes into production

Production of the first dishwasher pilot series began in October 1963 with ten appliances. The HSA household dishwasher made its first trade fair appearance in 1964, with volume production officially starting in March 1965.

Looking back, one of the Bosch engineers described the first dishwasher as “quite decent and usable for the time.” As most kitchens in the 1960s still lacked space for the appliance near the faucet and drain, it stood on caster wheels. To run the dishwasher, it was pushed to the sink, the water inlet hose was connected to the faucet, and the wastewater hose was placed in the sink. Quite apart from this rather cumbersome handling, there were other weaknesses: the interior of the machine, made of PVC-coated sheet steel, was susceptible to rust; and the design with only one spray arm also proved problematic. From its position on the appliance’s floor, this had to reach the dishes in both the lower and upper baskets. The only way to achieve reasonably clean dishes was to put the water under high pressure, which resulted in a lot of broken pieces.

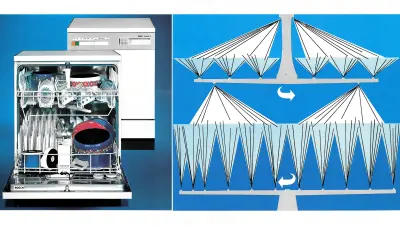

Further development into a top product

The second generation of dishwashers, which went into volume production in 1969, brought important improvements. A stainless steel container solved the rust problem, enabled faster drying, and was more hygienic overall. A separate spray arm was introduced for the upper dish basket. The appliance had better dispensing systems for detergent, rinse aid, and salt, and it was considerably quieter than the previous model. Its design was also refreshed, and the program sequence display with illuminated fields looked very modern. The most important thing was, of course, the dishwashing performance: its excellent results turned the machine into a top product.

Suitable for any kitchen

Thanks to continuous refinement, dishwashers became quieter, more efficient, more economical, and cheaper to buy. Step by step, they became integrated into fitted kitchens — in the 1970s via adapted dimensions and frames for decorative panels, followed in the 1990s by locating the controls along the top edge of the door so as not to disrupt the continuity of cabinet front panels. Since 1985, Aquastop technology has protected against water damage by stopping the flow of water in the event of a leak.

Quiet, clean, and economical

In 2000, Bosch presented the first fully automatic dishwasher. Sensors measured the degree of soiling and then adjusted the washing time, temperature, and amount of water. The “automatic dishwasher” delivered a further significant reduction in water and energy consumption and set new standards in the dishwasher market. In another major boost to energy efficiency, the Zeolith drying system was introduced in 2008. The mineral zeolite is characterized by its high water absorption capacity. When it stores moisture, it releases energy in the form of heat. The warm air flows back into the machine’s interior, both accelerating the drying process and shortening the washing program. This can save up to 20 percent energy per wash cycle.

Today’s appliances have a clear advantage over hand washing dishes: the automatic dishwashing cycle uses less water and energy, saves time, and saves people a lot of laborious work. Expressed in figures, the history of the dishwasher paints an impressive picture: 60 liters of water and an energy consumption of 2.3 kilowatt hours per wash cycle in the 1960s have now become 6 liters and 0.5 kilowatt hours in the eco program.

Author: Bettina Simon