COLLIE: Cost-effective combination of domain knowledge and data

In Bosch’s “COLLIE” project, Bosch employees from a range of divisions are working on a generalizable method which as a hybrid model combines domain knowledge and data in an intelligent manner and allows production processes among other things to be developed much more quickly.

At Bosch Research, our aim is to understand our product development and production processes with the help of suitable models. While many of these models are typically based on engineering or scientific ideas and formulas, methods involving artificial intelligence (AI) and machine learning provide new ways of generating models from data. Inspired by the IBM manager and visionary John E. Kelly (“Smart Machines – IBM’s Watson and the Era of Cognitive Computing”, 2013), Bosch’s “COLLIE” (Collective Intelligence Excellence) project takes advantage of the benefits of classic engineering disciplines and sciences as well as artificial intelligence and machine learning. By combining the best of both worlds, the COLLIE approach not only saves time and money in all stages of development – it also ensures quick knowledge building, clarity and trust. Regardless of whether it is used in research, development or production, the COLLIE approach chosen can be used to advantage in most problem classes such as optimization, transfer learning, prediction and problem solving.

The opportunities revealed by COLLIE are wide-ranging. For example, physical and analytical models and data can be used to generate so-called hybrid models. The advantage here is that the scope for solutions in the problem class for optimizing processes in production or development can be narrowed down considerably. As a result, the same or better optimization results can be achieved within days or hours – in contrast to the “classic procedure” where months or even years can pass owing to planning and extensive testing under real conditions.

The AI algorithms used for optimization and transfer learning as well as hybrid models from reinforcement learning are available throughout the company as software packages including tutorials. A software platform for production technology which includes system orchestration together with data handling and integration of the AI algorithms used is currently being developed by Bosch Research together with Bosch’s Powertrain Solutions division at the Hildesheim plant and Bosch Manufacturing Solutions . Other tools developed by Bosch Research will be available throughout the company by the end of the COLLIE project. The focus here is on requirements development and visualization in the problem classes optimization and transfer learning as well as prediction and problem solving by generating physically plausible equations or hybrid models from the given data.

The COLLIE cycle sets the pace

The collie is a breed of herding dog from Scotland. It is regarded as highly intelligent, capable of learning and obedient and can even make its own decisions. The dog is therefore the ideal symbol for Bosch’s COLLIE project. One specific case in which the COLLIE method was used was designing, setting up and using self-learning, fully automatic production machines in laser material machining. Like the herding dog, the machine should use existing knowledge obediently but then make its own decisions without human intervention and continue learning in order to optimize the production process. This means that the experiments for meeting the requirements were not only planned but also carried out and evaluated in a fully automatic, connected manner. As a result, the COLLIE laser material machining prototype is the “AIoT in pure form” – after all, it combines the benefits of artificial intelligence with the opportunities resulting from connecting machines.

“The variety of products that Bosch manufactures is growing day by day,” said Peter Stritt, an engineer at the Bosch Research center in Renningen. However, the production processes must be optimally matched to the particular requirements before production can begin. Given the increasingly short product cycles, this must be done as quickly as possible. “During the COLLIE project, we’re therefore working on a general method which will reduce the development time by optimally combining domain knowledge, measured data and artificial intelligence,” explained Stritt. Engineering, scientific and IT staff as well as a number of Bosch divisions are involved in the project – these include the Bosch Research center in Renningen, Process Development within the individual Bosch Powertrain Solutions plants, Bosch Automotive Electronics and Bosch Engineering GmbH - Chassis Systems Control, the Software Development in Hungary, the Bosch Center for Artificial Intelligence (BCAI) and Bosch’s own industrialization partner Bosch Manufacturing Solutions.

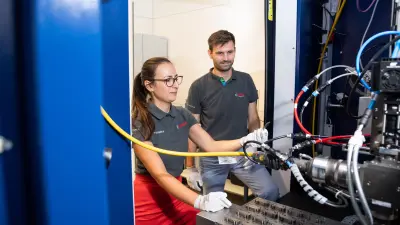

The benefits of the COLLIE method could easily be seen when producing the electromechanical brake booster developed by Bosch. During production, parts must be welded together using various techniques including laser beams. The COLLIE team optimized this process with the help of the prototype AIoT laser welding system developed at the Bosch Research site in Renningen.

“The aim of our expert team was to improve the quality of the welding results by significantly reducing contamination owing to welding spatters. Our vision became reality: The number of spatters was reduced by around 50 percent. Not only that, on the basis of our method, we’ve reduced the process time by 40 percent,” said project team member Tsvetelina Yordanova, an engineer at Bosch’s Blaichach production site. The next step involves implementing the process optimized with COLLIE in the production line for the iBooster in Blaichach.

One approach for everyone

With COLLIE, the project team has come up with a general procedure during projects which allows all possible processes to be used – both in production and in research and development. “The methods used for optimization, hybrid models and transfer learning are now available to all Bosch employees on the Bosch Social Coding platform,” said Yordanova. According to Peter Stritt, the vision goes one step further: “If we think of production in the future where everything really is connected and AIoT machines are used everywhere, our procedure can help to optimize production continuously, i.e. during the ongoing process.”

COLLIE in use

The COLLIE method can be used in all AIoT-related processes in production or research and development. Pilot projects have already started in a number of areas including the following:

- Production / process development: Laser welding, laser drilling, screwing

- Production / robotics: Adjusting optical elements for imaging products (e.g. for the multi-purpose camera (MPC) in autonomous driving)

- And in other areas including fuel cells, electrification (e-machine), semiconductors / micro-electromechanical systems (MEMS)

Tsvetelina Yordanova

As a simulation and calculation engineer, Tsvetelina Yordanova contributed through her calculation expertise early on in the COLLIE project. The 29-year-old works in the Development department at Bosch’s plant in Blaichach, where she focuses on a range of areas including the laser welding process. During the project, the qualified mechanical engineer gained additional knowledge in the area of AI and looked in greater detail at various machine learning algorithms. At the moment, she is undergoing further training to become a data scientist.

Yordanova was particularly impressed with the way the international team made up of staff from various specialist areas worked efficiently with colleagues from other business divisions during the project. As a result of this, Bosch quickly obtained valuable results.

Dr. Peter Stritt

The mechanical engineer is based at the Bosch Research center in Renningen. The 39-year-old contributes to the project with his specialist knowledge of laser material machining. During the COLLIE project, he gained a great deal of additional knowledge because he is responsible for setting up the laser machine controlled by artificial intelligence and has defined the corresponding interface. The project was therefore an opportunity for him to build on his knowledge of AI-based optimization and data analysis at the same time.

For Stritt, COLLIE means variety and the effective bundling of various skills with a view to optimizing processes quickly and efficiently.