Planar robots – Contactless transport and positioning in high performance

Based on a new magnetic levitation technology invented at Bosch, our researchers created a contactless transport, positioning and handling system, the Planar Robot. While carrying a payload, a Planar robot moves in six degrees of freedom with high speed, high precision and without any friction or contamination. Many of them can be operated simultaneously on a scalable platform, the stator. Modular and easily adaptable, they can be applied in a broad range of industrial sectors, from semiconductors to food, pharmaceuticals and assembly. Since 130 years, Bosch is continuously at the forefront of technological innovation, making it accessible to improve our quality of life.

The potential of levitation

Levitation may be common in science-fiction films, but in the real world, it’s very hard to achieve. In fact, Samuel Earnshaw, a 19th-century physicist, found it impossible to create an arrangement of magnets that stably levitates in six dimensions. Our permanent magnetic levitation technology overcomes the restrictions of Earnshaw’s theorem. Levitation holds tremendous potential for a variety of industries. Imagine energy-efficient transportation of all kinds of goods without wear or friction on movers that can freely move horizontally, vertically and in overhead operation. Bosch Research is now transforming this vision into reality.

Solving an age-old problem

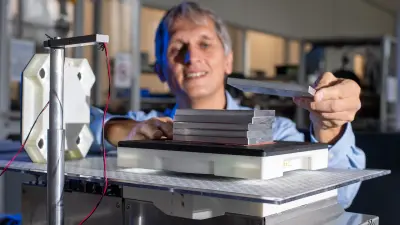

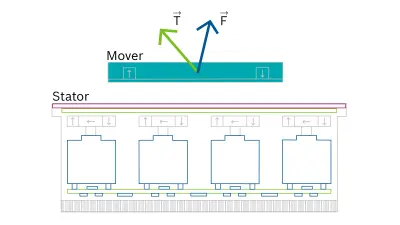

Planar robots are comprised of two main components: a mover and a stator, each of which contain permanent magnets. The magnets in the stator create a strong magnetic levitation field for the mover, which hovers silently approximately two centimeters above it. “To overcome the limitation of Samuel Earnshaw’s theorem, the levitation field is controlled by changing the rotary position of the stator magnets,” explains Joachim Frangen, Chief Expert for Production Automation. A hybrid AI control determines the precise arrangements of the magnets to steer the mover in six degrees of freedom.

The role of control

To get the mover levitating along a desired track, three steps happen in real time: sensing the position of the mover, processing the data, and then controlling the mover position by actuating the stator magnet angles. “If you can make it to control all six degrees of freedom, you will get the mover levitating”, says Frangen.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

Much more versatile and adaptable

Planar robots can be used to transport, handle, process and test goods in a variety of industrial applications. “They are much more versatile and adaptable than a conveyor belt – ideal for flexible production in sectors like semiconductor manufacturing,” says Frangen. “Levitation can also reduce the risk of contamination in food or pharmaceutical factories, potentially even high-throughput laboratories for something like Covid-19 testing,” he adds.

Areas of application

Semiconductor

Industry 4.0

Pharmaceuticals

Food

Laboratory

High payload

Advantages of planar robots compared to coil-based systems

- Maximum force/torque: 1-2 magnitudes higher

- Levitation distance: approx. 10 times higher

- 6 degrees of freedom, including full rotation around Z axis

- Low power consumption, independent of payload

- No surface heating, fan cooling

- Intrinsic safety, low magnet volume,

- Soft landing and safe parking at power fail

- Scalable (size, payload, performance)

Summary

Bosch is bringing levitation to Industry 4.0. AI-powered planar robots enable flexible, contactless transport and positioning for a variety of industries. The new permanent magnetic levitation offers a fundamentally higher potential than coil-based systems.

Podcast about planar robots and hoverboards

The intelligent combination of human knowledge and AI capabilities enables new products like planar robots. Hoverboards are no longer a sci-fi-gadget. In this podcast episode, Joachim Frangen talks about his invention. And Zico Kolter, chief scientist of AI research at the Bosch center for artificial intelligence, explains why Bosch AI is safe, robust, and explainable. Learn more about planar robots and hoverboards in the Bosch Global Podcast From KNOW-HOW to WOW.