Heating concepts for the future

The 1976 Bosch “Tritherm” research house

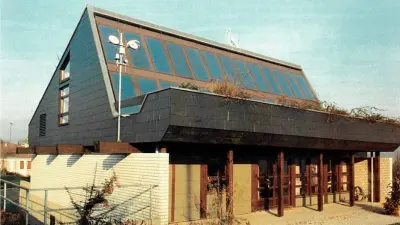

Conserving resources and preventing emissions are top priorities today when it comes to developing heating technology, both at Bosch and at other manufacturers. But what are the roots and pioneering achievements on which the current technological advancements are based? A look back at the past reveals one particular project half a century ago: the “Tritherm” house. Built in Wernau in 1976 and opened in 1977 for researchers working on the energy-efficient and resource-friendly thermotechnology of the future, the project was as unconventional as it was visionary.

In the shadow of the oil crisis

Hot running water and warm radiators have been standard in Europe since the mid-20th century. Central heating and a constant supply of hot water have long been a matter of fact. But in 1973, the first oil crisis drove home for many that such advancements should not be taken for granted. The finite nature of conventional fossil fuels such as coal, oil, and gas prompted researchers in many different fields — not just in heating technology — to search for alternative sources of energy that would help conserve resources.

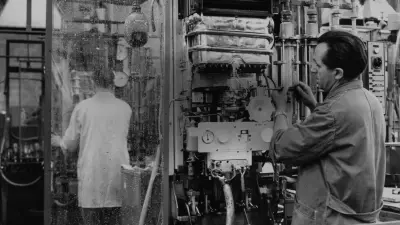

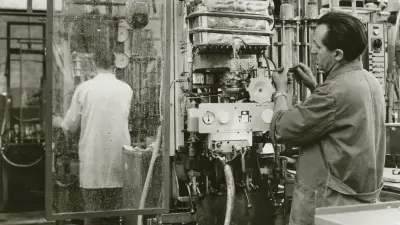

Time and again, researchers at Bosch have chosen to take an unconventional approach. That became apparent at Thermotechnology in early 1976 in the form of a very special construction site. Junkers, a division of Bosch at the time, built a single-family home. But what was the house on the grounds of the plant in the Stuttgart-area town of Wernau for?

A single-family home on the factory site

The new building was not conceived as a place of residence or for office space, but was instead designed to be a test subject. Its purpose was to demonstrate ways to save resources and energies with the help of the latest technology under real-life conditions.

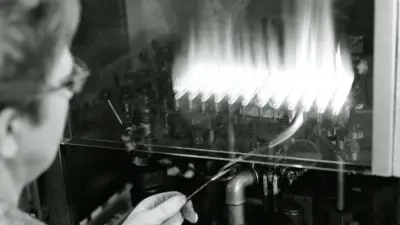

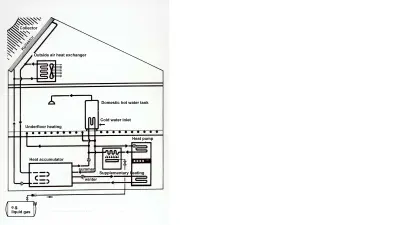

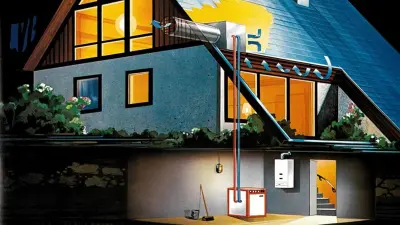

A conventional central heating system using liquefied petroleum gas was only there as a reserve for peak loads on the coldest winter days, for example. Otherwise, the rooms and water were heated by means of a heat exchanger that drew in air from outside, as well as 25 solar collectors measuring some 40 square meters. The name “Tritherm” was consequently chosen to reflect the three heat sources used.

The results were impressive, as researchers wrote in the publication “Bosch Technische Berichte” in 1979 — even though the question of financing still posed a problem:

“As the experience and measurements so far demonstrate, this makes it possible to lower the need for fuel to less than 10 percent of the previous level in our climate. The necessary investment still stands in contrast to the current cost of introducing such systems on a wide scale.”

An unusual test subject

The house undoubtedly looked somewhat unusual. On the south side of the building, where the solar thermal elements were mounted, the pitch of the roof was 60 degrees to ensure the calculated optimum solar heat output. Trial operations started around the time of the ISH trade fair in March 1977, with the house being unveiled to the public in May.

Depending on the attributes to be tested, different ways of using the combination of the three heat sources and a heat storage unit were made possible through a sophisticated system of valves and switches. Researchers had the option of testing 14 different operating states, including one that omitted the conventional gas heating system entirely and another that made use of direct supply without storage, allowing the house to heat water for use in the bathroom by using the solar thermal panels.

“This makes it possible to lower the need for fuel to less than 10 percent of the previous level.”

Presentable findings

The basement, accessible by way of a wide ramp, housed all of the technical equipment, including the heat storage system, heat pump, control system, and measuring technology. On the ground floor, a conference room and a meeting room were set up for inspections and presentations, with a large bathroom acting as a space for demonstrations. A deck was located around the side of the roof with the solar thermal equipment, allowing visitors to view it and enabling technicians to mount additional solar collectors for research purposes without scaffolding.

The entire project was an experiment that cost millions and was undoubtedly impossible for private builders and homeowners to reproduce. However, it demonstrated the full scale of what was technically feasible at the time and was a remarkable, pioneering achievement that seems visionary today. In addition, a research report published in 1979 illustrates that the project went well beyond merely examining ways to heat rooms and water by also including the use of residual heat in wastewater from processes such as showering, as well as reusing process water to save valuable drinking water.

Research and its real-life implications

Although nobody knew it at the time, the Tritherm house was the portent of a promising business field on which Bosch continues to focus to this day: intelligent energy management for buildings that makes clever and targeted use of energy sources not based on the burning of fossil fuels.

One of the pivotal technologies behind the resource-friendly generation of heat and finding innovative solutions to combat climate change is heat pumps. They draw in heat from the environment, from either the ground or outdoor air. With fossil fuels inexpensive and the urgent need for climate action far from the mind of the general public, the technology remained confined to the sidelines for a very long time.

Today, however, Bosch’s efforts to explore this topic since the 1970s are paying off. That is because the only energy a heat pump needs is electricity, which can be generated by solar panels on the roof of a house. The approach Bosch is pursuing is to make heating both carbon-neutral and affordable through renewable energies and smart connectivity.

Author: Dietrich Kuhlgatz