Can graphene-based conductors compete with copper in electrical conductivity?

Bosch Research Blog | Post by Martin Köhne, 2021-02-03

Co-author: Leo Rizzi Graphene, the atomically thin carbon layer with a hexagonal arrangement of the carbon atoms, is renowned for its outstanding electrical properties on the nanoscale. The electrical conductivity of a pristine, single layer graphene can be 70% higher than that of copper. I have wondered for years what is possible on the macroscale for graphene films and fibers. Therefore, my PhD student Leo Rizzi thoroughly investigated this topic in the last 3 years by means of simulation and experimental validation. The result of his work opens up new ways of how to increase the electrical conductivity of graphene in the macroscopic scale by up to 70-80% of its conductivity in the nanoscopic scale.

Discovery of graphene

In 1962, Böhm et al. published electron scanning microscopy pictures of carbon foils and named single layer carbon foils “Graphen”. In 2004, Geim et al. published about synthesizing single-layer graphene by using a scotch tape to remove graphene layer by graphene layer from a graphite flake until only one single layer of graphene remained. Since then, graphene has been one of the hottest scientific topics attracting significant interest and funding worldwide.

State of the art in macroscopic graphene

There is already a plethora of research on nanoscale applications for graphene. In recent years, the interest in research for macroscopic applications is also growing. Starting point for the synthesis of macroscopic graphene is typically a graphene powder dispersed in a liquid. Fibers or films are derived from such a dispersion by special processing such as wet spinning or filtration. Appropriate doping increases the electrical conductivity from app. 1 MS/m up to app. 15 MS/m. This is still well below the 100 MS/m of a single graphene layer. This difference is the origin of my motivation to understand what could be possible in a best-case scenario.

Approach for simulation

We modeled small units of a graphene film as a layered material consisting of randomly distributed but in-plane parallel graphene layers. Our model allows us to manipulate the average size and the size distribution as well as to use an arbitrary packing density. An important parameter is the spatial distribution within a layer, which varies from completely homogenous to heavily clustered graphene. Each flake obtained an individual but uniform in-plane electrical conductivity.

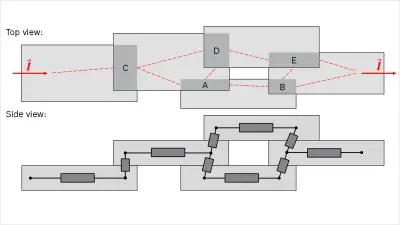

Next, we considered the overlap between the flakes by introducing the out-of-plane electrical conductivity and setting up an electrical network with nodes and edges as depicted in below figure. We determined in systematic parameter studies that the minimum required system size is 30 layers and 40 000 graphene flakes in total.

Result: Macroscopic graphene is able to outperform copper in electrical conductivity

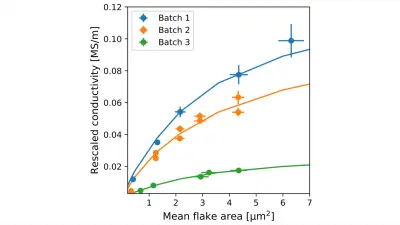

Our results show that there are two main parameters to obtain a high electrical conductivity for macroscopic graphene. It is crucial to have a high in-plane electrical conductivity in most of the graphene flakes. The value for the in-plane electrical conductivity determines the maximum possible conductivity. Of course, it is also necessary to reach a reasonable out-of-plane electrical conductivity. Nevertheless, the lateral size of graphene flakes compensates a lower out-of-plane conductivity to a certain extent due to the larger overlap area and the lower contact resistance as shown in the diagram below. The assumed in-plane conductivity used in the calculations of the diagram is 100 MS/m.

Appropriate tuning of these three major parameters will allow outperforming all metal-based conductors.

The experimental validation in the range of low electrical conductivity shows good agreement to the results from the simulation as seen in the diagram below. The lines represent the results of the simulation and the circles represent the experimental results.

Conclusion

Given as appropriate doping enables an in-plane conductivity of 100 MS/m for the graphene flakes with a flake size in the tens of micrometers, the macroscopic graphene can reach an electrical conductivity of up to 80 MS/m. A graphene-based conductor with 80 MS/m in electrical conductivity allows enormous efficiency gains, weight as well as volume savings and enables new designs for the powertrain in e-mobility.

What are your thoughts on this topic?

Please feel free to share them via ResearchGate or to contact me directly.

Author: Martin Köhne

Martin is project leader for disruptive conductor materials for e-mobility at Bosch Research. His current work aims at improving the property profiles of carbon nanotubes or graphene-based conductors to a level where they are able to replace copper in electrical powertrains.

Co-author: Leo Rizzi