Cloud Manufacturing: Where can you find a quick replacement when there is a production outage?

Bosch supports research project about online marketplace for production and transportation capacities

The sudden outage of a production facility, unexpected fluctuations in demand, material shortages at suppliers — there are many reasons why additional external production, transportation, and assembly capacities might be needed at short notice. This is where the broker for a dynamic production network (DPNB) research project comes in. Funded by the German Federal Ministry of Education and Research, the project aims to bring together providers and demanders via an online marketplace and enable supply chains to be set up at a rapid pace.

Time is money

Alongside Bosch, the consortium that jointly designed the online platform and built prototypes includes the Karlsruhe Institute of Technology (KIT), Forschungszentrum Informatik (FZI), and Bremer Institut für Produktion und Logistik (BIBA) as well as Trumpf, Transport Betz, and Bedrunka + Hirth.

Bosch heads up the consortium and is in charge of the pilot phase, which is based on a Bosch use case, and of migrating the research findings to other applications. “Our main task is to apply our logistics and purchasing expertise and ensure that the necessary information reaches the platform as efficiently as possible,” says Dr. Markus Bauer, Head of Logistics IT Solutions and Innovations at Bosch and co-initiator of the project.

Flexible value chain structures — effective disruption management

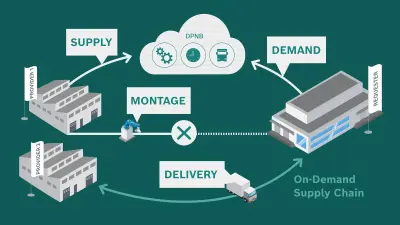

Time is money: Outsourcing production capacities at short notice means finding suitable suppliers as quickly as possible — ones that not only possess the technology and processes to make the required products, but also have resources available when needed. At the same time, transportation links have to be set up and tracked. The DPNB speeds up the search for capacity by automatically generating matches with providers and scheduling the related transportation processes. “This gives companies more options so that they can react much faster to disruptions,” says Bauer. “Putting together value chains reliably on an ad hoc basis also allows safety stocks to be reduced.”

“The webcrawler helps keep entry barriers and data maintenance work low while still generating sufficient data to enable highly accurate mapping.”

Partially automated onboarding of new suppliers

The goal is to integrate suppliers into the production and logistics network as rapidly as possible, while keeping data maintenance work to a minimum. “High-quality data is also required,” stresses Bauer. “That is the only way to fully exploit the DPNB’s potential.” The solution: A well-thought-out onboarding concept consisting of defined processes and queries as well as automated crawling of supplier websites.

On-Demand Supply Chain

Webcrawler supports data collection and maintenance

Using extractors (which rely on rule-based and NLP methods such as named entity recognition), relevant data points are pulled from the data collected from the crawled websites, classified by a machine learning program and automatically entered in the relevant fields of the DPNB. Companies can check and update their pre-entered data at any time. “The webcrawler helps keep entry barriers and data maintenance work low while still generating sufficient data to enable highly accurate mapping,” says Antonius Gress, Head of Digital Innovations, Software Development and Automation at Bosch Global Services.

Successful pilot network at Bosch

The DPNB concept was piloted by Bosch on an internal fuel rail production network, with the individual locations in the network acting as providers and demanders. Capacities were balanced using the DPNB, which was programmed and tested in close cooperation with the Homburg location — the lead plant in charge of production processes. The result: The DPNB delivered automated suggestions based on valid information that enabled quick action to be taken when disruptions occurred.

“We have benefited hugely from our involvement in the DPNB project and can use the experience and concepts when we develop new Bosch solutions,” says Bauer.