Fuel cell power and heat generation at the hospital

The energy of the future in critical infrastructure

When people think of innovation at hospitals, they usually think of new medicines or operating techniques. But innovation at the Hermann Josef hospital (HJK) in Erkelenz, Germany, has another dimension. Here, a more sustainable, hydrogen-based energy supply is being tested using decentralized fuel cell systems (solid oxide fuel cells, or SOFC) from Bosch. This pilot project is part of the Helmholtz Cluster (HC-H₂) at the Jülich national research institute, and is being conducted in partnership with Hydrogenious LOHC NRW GmbH, which developed the new H₂ storage technology.

Bosch’s operations relating to the industrialization and preparation for production of decentralized power-supply systems based on solid-oxide fuel cells (SOFC) were discontinued. Work to explore the possibilities of solid-oxide technology will continue within the company’s corporate research unit. Over the past ten years, Bosch has worked with partners to develop solid-oxide fuel-cell technology for decentralized power-supply systems. The achieved level of technical maturity has been demonstrated in over 100 pilot systems. The findings from the operation of the pilot systems are incorporated into the research activities.

A lot of energy for a day’s work

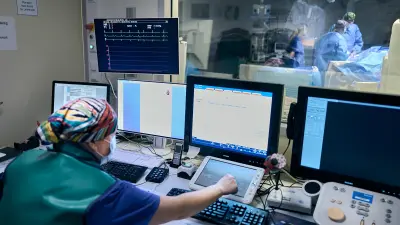

It’s a normal start to the day’s shift for Jessica Rama, head of the nursing team of the cardiac catheterization laboratory at the Hermann Josef hospital in Erkelenz. The hospital and its 400 beds provide health services to roughly 20,000 inpatients and 40,000 outpatients annually.

People with cardiac issues are treated here. Sophisticated technology detects vascular occlusion in the heart, and the specialists can widen vessels that have become constricted. As Jessica puts it, “Here we can give people back their health and quality of life.”

Having a reliable power supply is essential for us here at the hospital.

Like elsewhere in the hospital, the technology in the laboratory is highly sophisticated and complex, and a lot of energy is needed to power it. The electricity supply needs to be reliable and uninterrupted.

“Of course, this means that our carbon footprint is enormous,” she adds. But the hospital’s management is on the lookout for new solutions that will enable the enormous energy demands to be reliably met without taking a toll on the climate.

The vital importance of a stable supply

“Having a reliable power supply is essential for us here at the hospital,” Jessica says while showing us the cardiac catheterization laboratory. “If the power fails, a person could end up dying within seconds.”

The Hermann Josef hospital has immense energy needs: per year, it consumes 2.95 million kilowatt-hours of electricity. For the vitally important energy supply, the 100 kW-class SOFC pilot plant comes into play. When run at full capacity, the pilot SOFC system from Bosch can meet roughly 20 percent of the entire hospital’s electricity needs, in the process reducing its carbon footprint. This is because a fuel cell generates electricity and heat out of hydrogen and oxygen, with the only by-product being water, not carbon dioxide.

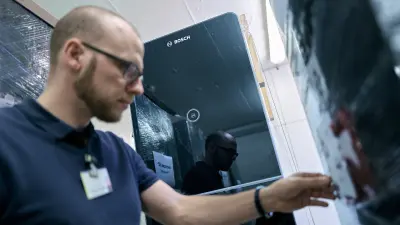

Jessica leads us across the courtyard to a low-rise building. There, directly next to the main building, stand ten futuristic-looking Bosch SOFC units, each almost two meters high. They can generate climate-neutral energy out of hydrogen.

This area falls under the purview of Tomasz Königs, a mechanical engineer by trade and the hospital’s technical manager, who together with his team is responsible for ensuring the supply of heat and electricity.

“We get most of our electricity from the public power grid, and this power is generated from lignite,” he explains. “The rest is contributed by a cogeneration plant running on natural gas.” We hear the latter rumbling in the background.

Technology for the energy transition

“We want to move away from fossil fuels,” Tomasz says emphatically. “Climate neutrality is an important vision for our hospital, especially in view of our enormous power consumption and our location here in the middle of the Rhine lignite region.”

Jessica can attest to this from her own experience: “I grew up nearby in Immerath, a town that was razed to make way for an open-pit mine.” A secondary site of the Hermann Josef hospital was also located there. It’s difficult to think of a more fitting — and more striking — contrast between fossil fuels and renewable energy.

Our hospital could become a role model for sustainable energy supply.

Fuel cell modules will not be meeting the hospital’s entire energy needs overnight. The system will run on natural gas at first, transforming it into hydrogen through a chemical process, until sufficient hydrogen from climate-neutral production is available. But even this first step will result in a 20-percent improvement in the hospital’s carbon footprint compared to the energy mix from the grid in this lignite region.

By the time the project — which is supported by the German federal research ministry — wraps up in 2026, the partners want to demonstrate that major facilities can be supplied with energy that is both climate neutral and reliable using fuel cell technology.

The energy supplied will not be only electrical energy, either. The Bosch SOFC system generates both electricity and heat, which can be fed into the hospital’s local heating grid.

For Tomasz, the next few years promise to be exciting: “Our hospital could become a role model for sustainable energy supply.”