Bosch windshield wipers: for a clear view in rainy weather

Nowadays we barely think twice about driving in wet, dark, foggy, or frosty conditions, but in the early days of the automobile this was a major challenge. Many “assistive” inventions in the 1910s and 1920s helped the new mode of transportation make a breakthrough. Following in the footsteps of the automotive light system, starters, and electric horns, the advent of Bosch windshield wipers in 1926 helped road users drive safely and in comfort.

The first functioning windshield wiper system was patented in the U.S. in 1903. It was invented by Mary Anderson from Alabama, who, during a winter visit to New York, saw a streetcar driver attempt to maintain good visibility despite freezing rain. She promptly sketched out a device consisting of a lever and an oscillating arm equipped with a rubber lip. The lever could be operated from inside the vehicle and made the arm move across the windshield.

In subsequent years, manual systems were joined by windshield wipers powered by the vacuum generated in the carburetor. The vacuum-powered models wiped the windshield at a variable speed, depending on how fast the engine was running. However, once the car reached its highest speed, the systems were either too slow or stopped working entirely.

The Bosch windshield wiper

Reliable visibility

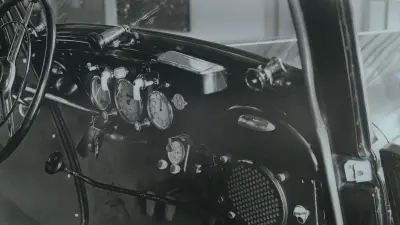

The new product from Bosch, unveiled in 1926, put an end to the troubles posed by weather and technical shortcomings. The system was powered by a small electric motor situated above the car battery and was not reliant on the engine running. Power consumption was reduced to a minimum, opening up the possibility of long journeys in wet conditions. There was also the possibility of adding a second wiper arm to keep the passenger side of the windshield free from rain and snow.

The electric windshield wiper soon became the standard. With the number of vehicles on the road rising consistently, demand for wiper drives and wiper blades also grew. A whole host of new innovations came in the 1960s, after the windshield wiper production at the Bühlertal location was expanded. The first of these, the “windshield washer,” as the windshield wiper system was known, came in 1959, along with the overlapping windshield wipers. To wipe the wrap-around windshields of the 1960s, the wiper blades in the new systems “overlapped” to push the wedge-shaped section in the center of the windshield not wiped by the blades further upwards, increasing the field of view. The blades were activated alternately to prevent them from colliding.

Innovations for the best wiper quality

Interval switches, rear wipers, rain sensors, and countless other innovations in wiper blade technology followed. Two different types of rubber were thermally bonded for the first time in the Twin wiper blades in 1994. The wiper lip made from hard natural rubber provided exceptional cleaning and a long service life. The rear element made of softer synthetic rubber was particularly resistant to the temperature fluctuations from summer to winter and made sure the system functioned smoothly. The next generation of wiper blade arrived in 1999 with the unveiling of the Aerotwin — the first blade without any joints or brackets. Here, the wiper rubber is pressed against the windshield through two curved spring strips and distributes the contact pressure evenly over the entire length of the wiper. The new system offers significantly improved wiper quality, with the flatter shape reducing wind noise and increasing the field of view.

Green light for Tienen

In the fall of 1970, the green light was given for the establishment of one of the world’s largest manufacturing sites for windshield wiper systems. Bosch and the Belgian city of Tienen reached an agreement on the formation of a company to manufacture electric and electronic equipment for the automotive industry. Construction began in summer 1973 and the first wiper blades came off the production line as early as April 1974.

In subsequent years, the location was expanded to become a development and production center for wiper blades and wiper arms. Manufacturing various types of rubber is just as much a part of Tienen as precision metal stamping, painting and surface treatment, modern assembly systems, and, of course, research and development in new and improved products.

Author: Bettina Simon