History of professional training at Bosch

From the Centralblatt to the yellow disk to web-based training

What would have happened if Robert Bosch had not continued learning for the rest of his life after leaving school and completing his apprenticeship in precision mechanics? Well, the company would probably no longer exist. After his apprenticeship, Robert Bosch would not have had the skills to set up the Workshop for Precision Mechanics and develop it into a global company. Thankfully, Bosch was a curious man who was always willing to learn new skills and train his associates. An overview:

In the company’s second year of existence, Robert Bosch subscribed to the magazine Centralblatt für Elektrotechnik for the princely sum of 20 German marks per year, equivalent to almost 30 hours’ wages at the time. Reading the magazine kept Bosch up to date with all the latest technical news. Over time, Bosch built up a small library full of specialist technical and commercial literature. In 1919, he expanded the library to include “recognized, high-quality works of literary fiction and of an entertaining nature” and opened it up to all associates at the Bosch location in Feuerbach as a works library.

The teacher-student structure was standard learning practice for many years. In 1913, for instance, a master class attended by 100 people was held at the University of Stuttgart, then known as Stuttgart Polytechnic.

Women joined Bosch’s production operations for the first time during the first world war, taking the place of men who had been called to the front. To accommodate the new associates, the tasks usually completed by skilled workers were broken down into lots of simple steps that could be performed by semi-skilled female workers. Skilled workers were only required to rectify any machinery malfunctions. This model proved so successful that it was retained after the war, increasing the number of semi-skilled workers — both male and female — in production.

Opportunities for advancement

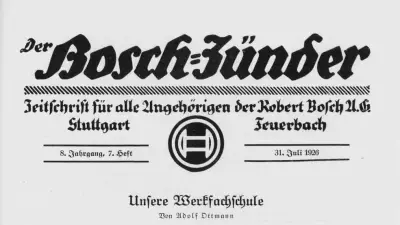

From 1924 onwards, senior engineers at Bosch taught essential practical skills as part of a specially established training scheme for skilled associates. Adolf Ottmann, head of the scheme, wrote that “highly capable skilled workers, engineers, master craftsman, quantity surveyors, and working students were to become proficient operations officers trained in the special requirements of mass production in precision mechanics and electrical engineering.” Candidates had to prove their suitability in an entrance exam. The scheme extended over an 18-month period and included 270 hours of learning organized after working hours. A great deal of motivation was required to complete the course, but those who passed the final exam were offered a permanent employment contract. The scheme offered solutions to multiple problems: Bosch gained the skilled workers it desperately required, and associates had the chance to further their careers within the company.

Earn while you learn

A renewed shortage of skilled workers was triggered by the rapid growth of the German “economic miracle” during the 1950s. The Spätlehre, a form of apprenticeship for adult workers, allowed semi-skilled works — including soldiers returning from the second world war — to complete their apprenticeship. Anyone who had worked for the company for three years and displayed corresponding suitability was free to apply. During the three-year apprenticeship, apprentices received 75 percent of their last salary, letting them earn while they learned.

In 1961, Bosch began systematic training for adult associates under the four-year step-by-step plan, allowing blue-collar workers to earn recognized professional qualifications or retrain without any loss of earnings. At the ceremony in honor of the first 34 graduates in December 1965, the graduates were said to be “all adult males, most of them fathers, who already had several years of service as semi-skilled workers under their belt, who spared no efforts and sacrificed their free time to gain the skills and knowledge necessary to qualify as skilled metalworkers.” Two-thirds of the men had previously worked in farming, carpentry, or as bakers. The plan was very popular, with 300 associates having completed the courses by May 1967. “Now I finally have a proper profession,” said one excited worker.

Outdated knowledge

“Bosch must do everything it can to offer older associates who are able and willing to learn, but whose knowledge has been overtaken by technological development, the chance to train and work in new areas of activities. The expenditure necessary for such training is justified, as losing the experience of such associates would prove unreasonable from a business and economic perspective.” These statements, taken from a board of management meeting in May 1979, show that the topic remained of critical importance as the decades went on.

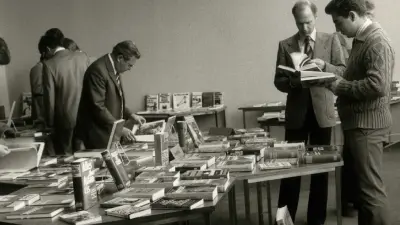

A number of initiatives were established on the basis of this attitude. In 1980, the Robert Bosch Kolleg was set up as a kind of internal company university. Here, college-educated specialists and executives were able to refresh their knowledge in what began as three-month learning cycles. They were relieved from their everyday duties to attend the courses. From 1984 onwards, skilled executives began holding talks on their work during working hours in Lernstatt groups comprising ten associates. The aim of these seminars was to improve associates’ understanding of the company’s inner workings while promoting the development of skills.

Yellow disks and web-based training

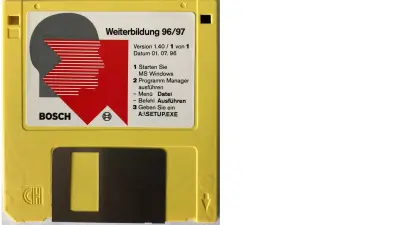

There was no let-up in the pace of technological change. The departments responsible for training not only updated the content of the courses, but also modernized the way training was organized and how people could sign up for it. A self-learning center, where associates could use learning diskettes to learn about data processing, was set up in Feuerbach in 1985. Three years later, the board of management created a new corporate office to deal with the principles of associate development. The promotion of independent learning using computers subsequently increased, and was met with a high level of interest. Associates requested around 14,000 computer learning programs within a short space of time. Bosch expanded the range of topics to over 200, available in a variety of languages.

But how did associates find and enroll for courses? The system may appear outdated to us now, but back then it was state-of-the-art: Werner Mehrling, head of technology and information processing at the corporate office for training, introduced the yellow disk in 1995. With the yellow disk, associates could install the electronic training catalog quickly and easily on their computers and sign up for courses. But the disks would become obsolete every year when the new training catalog was released. It took until 2014/15 before associates could search and sign up for the latest training courses at any time using the HR-Global tool. From in-person modules to web-based courses, it has never been as easy to access training as it is today.

Training courses were usually organized locally until 2009, when the Bosch Training Center (BTC) was established to provide central and standardized training for associates’ qualifications worldwide, with branches in Brazil, the United States, Germany, India, China, and Japan. The Robert Bosch Kolleg provides programs on leadership and transformation topics such as digital transformation, artificial intelligence, and artificial intelligence of things (AIoT) for specialists and executives.

Lifelong learning

Not only is the board of management a keen proponent of training, it also takes an active role. Lifelong learning has never been so important, both in view of the shortage of skilled workers and against the backdrop of rapid technological progress, the constant transformation of the employment market, and future standards and requirements. “We believe it is our responsibility as a company to equip as many associates as possible with the skills to take on new tasks,” says Stefan Hartung, chairman of the board of management. An inaugural learning event, the Global Days of Learning, was organized in October 2021. Bosch associates all over the world had an opportunity to take part virtually in informal training courses hosted by Bosch colleagues and share their knowledge with others globally, on a wide array of topics.