Industry for Individualists

Networking is revolutionizing industrial manufacturing

Custom-made shoes, personal porcelain decors, or self-designed cell phone covers — whether it’s luxury products or everyday items, our desire to own individual products is growing stronger, as the steadily growing range of product selections shows.

More individuality

This need is an expression of one’s own personality. This is also the reason why the model ranges of smartphone producers are becoming increasingly broader. Manufacturers want to cover even the smallest market niches. The same applies to industrially manufactured products such as cars. More and more series are designed to meet customer needs. The number of equipment lines continues to grow to allow for greater individuality.

Flexibility as a new form of customer service

But today’s range of selections is nothing compared to the possibilities of the future. Let’s accompany a young couple while they purchase a car in the year 2025: They don’t agree completely when it comes to the massage seat, but they both want the information display to be bigger. Not a problem. A tip of the finger on the configurator at the car dealer or on their PC at home is enough. But what if they also want the screen to be curved? Anything is possible.

Manufacturing of the future — Industry 4.0

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

Just another wiping movement of the fingers and the component takes on the desired shape. Even the borders of the screen, which they want to be very narrow and, secondly, be made of matt brushed aluminum can be entered into the system. In short, the choices are almost unlimited. Our car buyers return to pick up their unique vehicle only a short time later. Industrial automotive production as we know it today is still miles away. It needs to increasingly focus on producing individual products at the low costs of mass production.

Industry 4.0

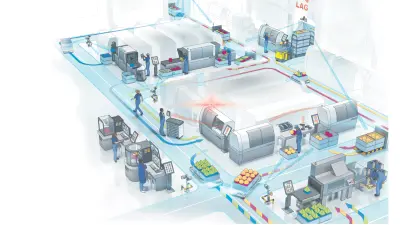

But the future has already begun in certain areas. It is called Industry 4.0. This is accompanied by a fundamental upheaval in industrial production. The main focus is on networking machines, components and IT systems. Machines and workpieces exchange information that is then processed in the cloud.

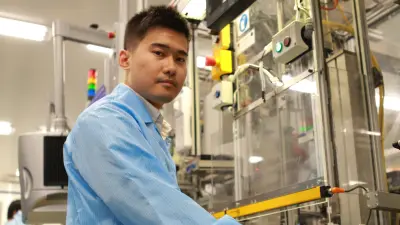

And what about the people? The employees have long become tutors and programmers. Much of this is intuitive because, with Industry 4.0, the machines are controlled via touchscreens and easy-to-understand user interfaces. Language barriers or complicated operating processes are therefore now a thing of the past.

“Anyone who can use his smartphone doesn’t need to be afraid of this,” explains Fabian Borowski. The 29 year-old is a “Digital Native” and an Industry 4.0 expert at Bosch Rexroth’s plant in Homburg/Saar. This plant has been manufacturing based on the laws of the Fourth Industrial Revolution since the summer of 2014.

The four industrial revolutions

The use of machines — the First Industrial Revolution

The first mechanical production plants that were powered by steam engines were installed at the beginning of the 19th century.

Piecework and assembly line work — the Second Industrial Revolution

As electricity became more widespread, production processes were automated and significantly higher capacities were achieved starting at the end of the 19th century.

Microelectronics comes along — the Third Industrial Revolution

The first large computers were put to use in the industrial manufacturing sector around 1970. Processes could then be controlled automatically.

The Internet of Things — the Fourth Industrial Revolution

The networking of products and goods enables production to be more flexible and allows for faster product adaptations.

Experience today how products will be manufactured in the future

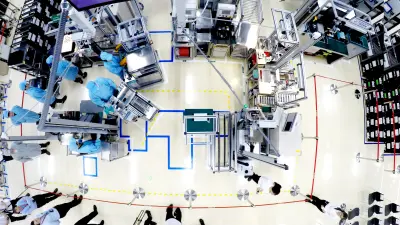

The plant manufactures hydraulic valves, which in itself would not be particularly exciting, if more than 200 different valves would not be produced on a highly flexible production line. This is made possible by applying an RFID chip to the valve blanks. The multiproduct line, which is assembled from nine production stations, reads it at every station using sensors. It then knows what needs to be done at the respective station.

Employees receive feedback from the machines. If an employee reaches into the wrong box of screws, for example, the system will warn him not to install this screw. The production line, which has already won several awards, is quite advanced. “It links people, machines, and products,” explains Frank Hess. He claims this will be the industry standard ten years from now.

Wishes are not the same everywhere

In the future, everything will be manufactured in a similarly flexible manner — including the information display that young couple wanted to have in their new car. There will be a difference, however, in that many more wishes can be considered. This diversity of varieties is what makes Industry 4.0 so interesting. Different product versions can be produced quickly to meet individual desires.

In the same way, it will be possible to react more flexibly to market changes and special factors. What happens to be a success in Beijing does not necessarily have to work out well in Tokyo, and certainly not in Europe. Industry 4.0 will give manufacturing companies the flexibility their customers are demanding.

Flexibility

This new flexibility not only means being able to produce many different components. It will also enable short-term changes to be incorporated into production at the last minute, if a customer makes a late request, for example. After all, as much as customers are longing for individual solutions, they don’t want to wait a long time for their orders to be filled.

Summary

The employees have long become tutors and programmers. Much of this is intuitive because, with Industry 4.0, the machines are controlled via touchscreens and easy-to-understand user interfaces.