Learning Control for Advanced Excavator Assistance Functions

Bosch Research Blog | Post by Adrian Trachte and Ozan Demir, 2022-02-14

With our team at Bosch Research, we are working on combining physical knowledge with data-based approaches in order to improve functionality and accuracy while decreasing calibration and development work. In recent years, there has been a growing interest in assistance and autonomous functions for working machines. This is enabled by new possibilities with electro-hydraulic operation systems, which are becoming almost standard for new working machines like excavators. Such features reduce the workload and increase productivity by removing responsibility for some challenging or sometimes tedious operations with high accuracy requirements. One of the most important technological requirements for developing these functions is the ability to accurately track paths. Since an experienced operator can follow trajectories quickly and accurately, and the demands on autonomous functions are equally high, simple, empirical controller structures will fail.

Action - Reaction - Realization

Action: Physical model

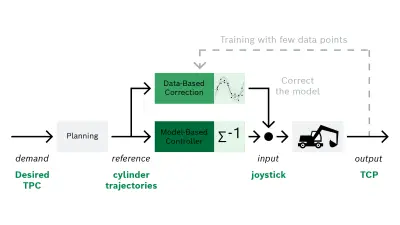

In general, hydraulic working machines like excavators are complex, highly non-linear systems. To compensate for the non-linearity of the system, we developed a model-based controller with a feed-forward path. Although the controller design took a lot of time, the initial results were promising as the controller could ensure accurate trajectory tracking.

Reaction: Too long, unknown components

However, it soon became clear that it would not be possible to develop such a control system for each machine.

Excavators are used for very different tasks in different environments and differ greatly from each other. Consequently, the excavator domain is typically a low-volume, high-mix ratio, making the development of complex system models for controller design financially unattractive.

Realization: Learning control

All these challenges promote the use of data-based control approaches. They can solve the control problem either by dispensing with a system model or by combining simple physical models with data-based models in order to improve model accuracy. This also leads to better path tracking accuracy. Hence, we have developed black-box and hybrid controller strategies with different data-based modelling frameworks. They replace or combine physical system knowledge with data-driven knowledge extracted from offline data. Consequently, the time and effort required for model development and calibration for the same controller performance can be reduced.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

The video shows an example of the calibration sequence of the assistance function, consisting of data collection, model training and finally, the excavator with its grading function at work. In active collaboration with our colleagues from Bosch Rexroth, we were able to transfer the results to two further excavators differing significantly in size and hydraulic topology. The results were published in the scientific community with good feedback as well as at the Bosch Rexroth exhibition MOBILE 2021 in September 2021.

What are your thoughts on this topic?

Please feel free to share them or to contact us directly.

Author 1

Adrian Trachte

Adrian joined Bosch Rexroth in 2009 as a PhD student working on Hardware-in-the-Loop Simulation for hydraulic valves. After joining Corporate Research, he worked on methods for adaptive and learning control and as a project leader. In January 2022, he became group leader of the Knowledge Engineering and Digital Twin Technologies cluster. Adrian is very enthusiastic about introducing new technologies to applications and loves working in a continuous-learning and open-minded environment.

Author 2

Ozan Demir

Ozan joined Bosch in 2012 after completing his PhD on networked control of interconnected systems. He has been working as a research engineer at CR since 2017. His main focus is assistance functions for working machines.

He is very curious and passionate about combining control theory with new machine learning methods and enjoys applying new control concepts to real applications.