Making hammer drills even smarter

A hammer drill and a mountain climber have something in common: their performance changes when the air gets thin. “At high altitudes, where the air is thin, you have to operate a hammer at a slower speed,” says Achim Düsselberg, a development engineer at Bosch Power Tools in Leinfelden-Echterdingen, Germany. “The transition from idling to running under load, as it is known, requires a different number of revolutions per minute depending on the altitude.” As a result, hammer drill users in China or Mexico have different needs than their counterparts in Germany.

This challenge is one of many associated with the development of new tools that a cross-divisional team of colleagues from Bosch Power Tools and Bosch Research has taken on – with resounding success. In 2021, a series of smart hammer drills that detect their requirements without human input is set to hit the market.

Rapid prototyping for the smart hammer drill

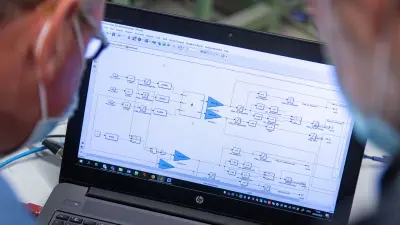

The scheduled launch shows that mountain climbers are not the only ones who need to persevere in the face of challenges. The alliance was formed roughly nine years ago. The team’s idea? A hammer drill that adapts automatically to its environment. As part of his job, Christian Bertsch from Bosch Research works with virtual prototypes. For their tests with the smart hammer drill, he and his colleagues used an approach that is common in the automotive sector but was still uncharted territory for Power Tools at the time: simulating electronic functions on a computer. “We have the advantage that Bosch Research works with various different divisions,” says Power Tools associate and software engineer Hagen Keinath. “That allowed us to work with the research colleagues to transfer the software functions from the automotive world to Power Tools.”

During the simulation, the team identified where the hammer drill offered potential for improvement. “We want to make work as easy as possible for customers,” says Steffen Tiede, business owner at Power Tools. “The aspects of weight control and performance are just as important as smooth starting on the wall.”

7 sensor concepts

were evaluated in the development of the smart hammer drill

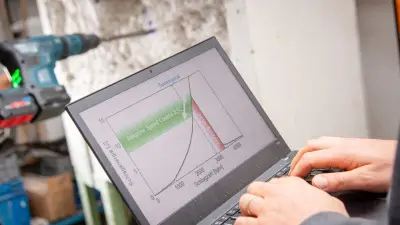

For the development of the smart hammer drill, the researchers adapted the rapid prototyping system from the automotive sector to the needs of Power Tools. With that goal in mind, a test hammer was connected to the prototyping system in order to permit immediate testing of the various software functions on the tool. “To make a hammer smart, you need sensors and algorithms,” Christian Bertsch explains. “We looked at seven sensor concepts for the tests, plus we checked whether they would withstand the conditions on a building site.”

Adaptive Speed Control

At the start of their collaboration, the team focused on equipping mains-powered hammer drills with sensors. The new series is cordless. “With the sensors, the hammer automatically detects which speed it needs, among other things,” says engineer Steffen Tiede. “That way, it doesn’t waste any unnecessary energy while idling, plus it’s more comfortable for the user to handle.” For example, users no longer experience any kickback from the tool when they start working on a wall. Thanks to the sensors, the hammer also knows whether or not it is already in front of the wall. The technology is known as adaptive speed control. It enables better starting behavior so that users can control speed better.

The smartphone app makes it even easier

“Bosch Research even set up a hammer drill laboratory for a while,” says Hagen Keinath, who implemented the sensor-based functions in the power tools. “We then all tested new functions on-site on a two-ton concrete block.” Today, the team has registered 17 patents together, including the combination of various functions with a sensor and the use of a smartphone app to adjust parameters – yet another function that makes it easier for users to work with the hammer. The tool can be linked up with an app, allowing users to take advantage of a host of functions, such as setting the work mode in which the hammer should run in advance.