SOFC goes off-grid — a multidisciplinary challenge: from electrochemistry to cloud

Bosch Research Blog | Posted by Maxime Carré and colleagues, 2023-02-08

Co-authors: Bernd Bohnet, Felix Schaefer, Gabriele Michalke, Matheus Montanini, Michael Stauch, Paul Kiessling, Sebastian Egger, Sebastian Schmaderer.

Climate change poses one of the major challenges of our time. At the same time, the demand for electrical energy is rising worldwide — be it the increase in electric vehicles, heat pumps or digitalization (IoT, Big Data). This time it will not be as easy as simply building more power plants. The solution must be green (low or even no CO₂ emissions), distributed (where power is needed) and fast (rapidly growing digitalization).

Stationary solid oxide fuel cells (SOFCs) for distributed power generation will play a crucial role in this future solution. The SOFC system by Bosch is currently under development preparing for serial production. An overview of this promising technology and the related change in the many associated research tasks is provided below.

It starts with an efficient power generator, a solid oxide fuel cell ...

Simply speaking, an SOFC system generates electricity and heat in an electrochemical process from a fuel, see Figure 1. Ideally, the SOFC is operated with hydrogen. If sufficient green hydrogen is available in the future, SOFC technology will produce power without any carbon emissions. Already today, when the system operates with natural gas or biomethane, carbon emissions are reduced compared to power generation from coal (with biomethane carbon emissions drop to zero already today). On top of that, SOFC exhaust gas does not contain any nitrogen oxides or particulates. As the SOFC unit can be fueled with natural gas, biogas, hydrogen or a mixture of them, it is one key technology for the energy transition.

This fuel flexibility is a clear advantage of this innovative technology. But there are more: The SOFC unit achieves a net AC electrical efficiency of more than 60% and, with additional use of the generated heat, an overall efficiency of more than 85%. At Bosch Research in Renningen Germany, we even measured a net AC LHV efficiency of 65% for a SOFC prototype unit in part-load operation. This enhances the SOFC playing field to many different applications.

When it comes to producing electricity efficiently from chemical energy (hydrogen, natural gas, ...), fuel cell technology is generally the right solution. A simple comparison with internal combustion engine technology substantiates this statement. As depicted in Figure 2, a fuel cell is able to convert chemical energy into electrical energy directly. This single-step transformation reduces losses. Nonetheless, efficiency is only one possible technical parameter in assessing a technology. Further parameters shall be considered to fully investigate the pros and cons of various technologies.

Self-made prototypes were developed and commissioned by a multidisciplinary team. Indeed, fuel cell systems require multidisciplinary knowledge, ranging from thermodynamics over electronics up to fundamental chemistry. Simulation and control strategy development have not been forgotten.

SOFCs are maturing — It is time for off-grid!

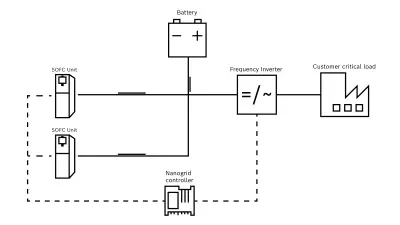

As SOFC units mature, it is time to off-grid! What does off-grid mean? A critical electrical load (in a factory, a data center, etc.) can be powered solely by operating several SOFC units, batteries and additional electrotechnical components. Figure 3 gives a simplified overview of possible electrical wiring for such a system.

The SOFC units deliver power for medium- to low-dynamic phases, whereas the battery delivers power for highly dynamic phases. Several SOFC units are connected, which simplifies maintenance, increases power-production availability, and at the same, opens many new operating strategy possibilities in terms of power modulation.

While the diagram in Figure 3 looks “pretty manageable,” it dissimulates several challenges we had to solve.

First, in many applications, a certain redundancy is required. This means that several components of the previous figure have to be duplicated, wired, and dynamically switched according to the critical load. So the complexity is in the details. As Bosch, we have had decades of experience with the development and series production of technically complex products. Together with the multidisciplinary know-how described above, we can now draw on this experience when developing and manufacturing our SOFC systems.

The sizing of such a system adds another challenge. There is always ideal sizing (size of the battery, size and number of SOFC units) to address customers’ technical needs or energy requirements. This technical optimum has to meet economic limits of the use case. On top of that, customer needs may change during the lifetime of such a system. As it is about powering a critical load off-grid, this solution should be scalable on-site. The Bosch SOFC offers a lot of flexibility in this regard. Depending on energy requirements several SOFC units can be connected with each other, enabling scalability up to the megawatt range. Also, the number of SOFC modules can grow flexibly. For instance in a data center, the SOFC system can offer a power supply that can flexibly grow with the IT infrastructure if you want.

The last challenge concerns the control of the SOFC unit, the battery and their electrical switches. We consider well-known AI tools as key to solve this last challenge, combining our engineering know-how with AI expertise.

Conclusion

From the beginning, SOFC technology required multidisciplinary know how: thermodynamics, chemistry, material science, control theory, etc. Now SOFC systems are pretty well understood and only a few steps are missing to achieve mass production. A promising future use case is the powering of critical loads off the grid or with only partial access to the grid – this will create new market opportunities.

What are your thoughts on this topic?

Please feel free to share them or to contact me directly.

Author: Maxime Carré

Maxime completed a French/German mechanical engineering degree specializing in control theory. This background underscores his broad technical and scientific understanding, which he believes is really crucial when it comes to electrochemical systems. He has been developing a stationary fuel cell system for 12 years and, more recently, an electrolyzer system. As one of the research associates with the longest experience in this field, Maxime likes to describe himself as the “living encyclopedia” of stationary fuel cell systems. He is eager to continue this journey along the electrolyzer route.