Reinventing braking

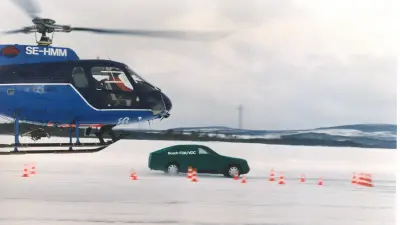

Putting brake-by-wire through its paces on the Arctic Circle

Brakes have always been among the most vital components for vehicle safety. Ever since it premiered the servo brake in 1927, Bosch has been continuously tweaking the way brakes work. Bosch engineers reached further milestones with the debuts of the antilock braking system (ABS) and the electronic stability program (ESP®). Now the next big leap forward is about to be launched — brake-by-wire. But how well will the system work in snow, ice, and temperatures down to minus 25 Celsius? Just a few miles from the Arctic Circle, Bosch engineers put it through its paces.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

High tech significantly made in Abstatt

When asked about this innovation from Abstatt in Germany, Hagen Kuckert says: “While traditional brake systems feature a mechanical connection between brake pedal and brake system, our brake-by-wire system does away with this completely. If drivers want to brake, this intention is transmitted as a purely electrical signal through redundant — completely discrete, in other words — signal lines.” For this radically new approach, Bosch offers a robust and efficient solution comprising two hydraulic brake actuators — the by-wire brake actuator and an ESP®. Kuckert is the project leader for the by-wire brake actuator and collaborates closely with a roughly 60-strong core team working not only in Abstatt, but across the globe. Its work is fast and agile — development took no more than roughly three years. For Kuckert, there is absolutely no doubt that brake-by-wire is the brake system of the future: “As early as 2030, we forecast that more than 5.5 million vehicles worldwide will be equipped with brake-by-wire.”

As early as 2030, we forecast that more than 5.5 million vehicles worldwide will be equipped with brake-by-wire.

Lighter, safer, more flexible: the advantages of brake-by-wire

The chief advantage of brake-by-wire is that installation is more flexible, creating new possibilities for the interior design of vehicles. As there is no longer any mechanical connection, brake system components no longer have to be mounted on the vehicle’s firewall. Instead, the components can be installed where they make most sense in terms of crash safety, NVH, and manufacturing.

“In the market, Bosch is one of the leading suppliers offering this advantage of flexibility with its brake-by-wire solution,” Kuckert says. Having the freedom to choose where the brake actuators can be installed obviates the need for left- and right-hand-drive variants.

Its slim design means less space is needed for installation, and that the braking system is lighter. Compared with conventional braking systems featuring redundancy, it can be up to 25 percent lighter. As the by-wire brake actuator and the ESP® are assigned to separate channels of the redundant electrical system, they can build up brake pressure on all four wheels independently of each other in the event of a system failure. This makes the Bosch solution suitable for highly automated vehicles as well, as it meets the safety requirements for such vehicles’ brake systems.

On top of that, Bosch is once again helping to avoid injuries in the case of accidents. Because of the crash-optimized way all the brake components are installed, and because of the new pedal designs without any mechanical connection to the braking system, foot injuries in particular can be reduced.

And how does brake-by-wire feel in practice? “There’s no difference in braking experience and safety. And that’s just what drivers want,” Kuckert says. But is that really the case in everyday conditions and on country roads? To answer that question, it was subjected to an endurance test almost exactly three years after the start of the project. In December 2024, trials on public roads were given the official go-ahead.

From Abstatt to Sweden, taking in the Arctic Circle

This was where Uwe Ongert came in. One of the “midwives” of the brake-by-wire system, the systems integrator has been on the project since it began. He takes things that work in theory and puts them into practice. “Leaving the proving ground for Sweden was definitely the highlight of this project for me,” Ongert says. At the end of last year, he and a small team set off to Sweden from their southern German base in Abstatt. It was a 3,300-kilometer drive on roads of different kinds: country roads, freeways, urban roads — with a short detour to the Arctic Circle. After six days, the vehicle reached Vaitoudden, the site of the Bosch winter test center near Arjeplog, northern Sweden. But could the system pass the acid test of the Swedish winter, with its sub-zero temperatures?

Customer feedback — essential for a successful market launch

Up near the Arctic Circle, the conditions are perfect for putting brake-by-wire through its paces. “During the winter season, we alternate between two weeks in Sweden and one in Abstatt. The days are long and intense, but the close collaboration between the Bosch team and customers means we make huge progress in very little time,” Ongert says. His enthusiasm for the system, his job, and the test drives is palpable. And customers are also excited by the “Invented for life” spirit. “The proof of the pudding is in the eating. That’s why we’re so glad that our customers can try out the system for themselves here in Sweden. And in its turn, their feedback finds its way straight back into the development process,” the systems integrator says, summing up the benefit of testing in Arjeplog. For Ongert, these are the project’s final test days of the winter in sub-zero Sweden: “I’m very proud that we will be going into volume production before the year is out.”

The first orders are in — from fall 2025, brake-by-wire will be on the roads

Market launch of the Bosch hydraulic brake-by-wire system is planned for the fall of 2025. European and Asian automakers have already placed orders. In addition to its hydraulic solution, Bosch is also developing a purely electromechanical system.

At all events, Hagen Kuckert and Uwe Ongert agree that brake-by-wire is an important component for software-defined mobility and automated driving from Level 3 upward. This makes it a solution with a great future — whether in wintry Sweden, southern Germany, or anywhere else in the world.

Proving ground near the Arctic Circle

Trials in extreme conditions have always been crucial for a successful market launch. This was also true for the antilock braking system (ABS), which Bosch began to develop in 1969, and which had to work reliably in all temperatures. But using public roads for these trials soon proved to be a problem: so as not to endanger other road users, it was not possible to treat the test routes. But the trials needed specially treated surfaces.

Finally, in the 1970s, Bosch hit on the solution — a frozen lake near the northern Swedish community of Arjeplog. On the thick ice covering the lake, engineers could carry out their test drives without endangering others. All drivers had to do was make sure their vehicles didn’t get in each other’s way.

In 2003, Bosch set up a larger test center near Arjeplog on the Vaitoudden peninsula, roughly 60 kilometers south of the Arctic Circle. To this day, Bosch systems — especially advanced braking systems — are tested in extreme cold and ice, on an area the size of nearly 600 soccer pitches. And while little has changed in the surrounding area since Bosch started testing there, the technologies have come a long way. Today, a laptop is all that is needed to adjust the parameters of the brake system for test drives. Fifty years ago, engineers still had to use soldering irons.

30 years of ESP®

A success story

For 30 years now, the electronic stability program (ESP®) from Bosch has been an impressive success story. Since its launch in 1995, Bosch has sold more than 350 million units of this innovative system worldwide. This figure illustrates not only how readily drivers have accepted this technology and the trust they place in it, but also the decisive role ESP® plays in the automotive industry.

What is particularly striking is the impact ESP® has had on road safety. Bosch accident researchers calculate that the system has saved more than 22,000 lives in the European Union and the United Kingdom alone over the last three decades, preventing almost 750,000 accidents involving personal injury. These impressive statistics underscore how indispensable ESP® has become as a safety system in modern vehicles.

The technology has not only helped enhance the safety of vehicle passengers, but also boosted general confidence in driving. With every unit sold and every accident prevented, the success story of ESP® will continue, and Bosch will remain at the cutting edge of work to develop innovative solutions to improve road safety.