The history of environmental protection at Bosch

Conserving resources and acting responsibly

At Bosch, responsibility and resource conservation go all the way back to the company’s founder, Robert Bosch. On the shop floor, he had signs put up reading “Save water!” and bearing other reminders to use resources carefully. This early stance became part of the company’s DNA. The many small achievements in the early years that boosted the company’s economic efficiency soon developed into clearly defined initiatives and the foundation of its strategy as the company developed.

“Turn those spare lights off!” Everyone was familiar with these warnings, from the young apprentice who first saw Robert Bosch making the rounds of the workshops, to the bookkeeper who saw the company founder rounding the corner from his position at the first desk up front. Robert Bosch’s aversion to wasting electricity and his thunderous reproaches for any associate discovered doing so took on an almost mythical status. But it was much more than just one of his particular idiosyncrasies. From the early days of his workshop, Bosch was focused on not wasting resources. For him, a keen sense of economic efficiency and a far-reaching awareness of responsibility were fundamental for successful business.

The era of environmental awareness

In general, several factors led to a rise in general environmental awareness and the first environmental policy measures in industrialized countries in the early 1970s, which also had an impact on Bosch. The economic boom of the 1950s and 1960s, with its rapid growth in industrial production, resulted in a noticeable, negative impact on the environment, particularly in Europe and North America. Studies critical of growth, such as the Club of Rome’s 1972 report “The Limits To Growth”, and international initiatives, like the United Nations Conference on the Human Environment first held in Stockholm that same year, caught the world’s attention.

Rules for environmental protection at worldwide locations

In its “Research and development” section, Robert Bosch GmbH’s annual report for 1970 mentioned “Environmental protection” for the first time. Key aspects included noise reduction in production and in the products themselves, wastewater treatment, and the mitigation of harmful emissions through the advancement of fuel injection technology.

The first extensive measure taken at Bosch was the first set of environmental protection guidelines, which took effect on January 1, 1973, underscoring the growing importance of environmental protection. During the same period, investments in environmental protection projects throughout the entire Bosch Group rose year by year. Admittedly, the need to comply with increasingly stringent legal regulations was to a large extent responsible for the steady rise in environment-related expenditure. However, as stated in the standard, Bosch was also committed to seeking out new, more eco-friendly equipment and systems in order to “continue to improve conditions within the company and work in the public interest.”

Focus on environmental protection and resource conservation in products

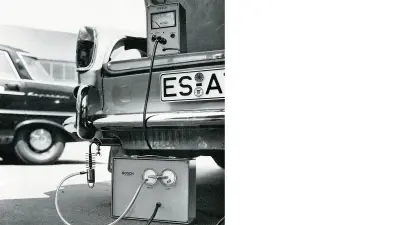

Environmental protection was not simply limited to an anchoring principle in corporate activities. Instead, it was also established as an element in the development of products. In 1967, Bosch took a crucial step toward reducing car exhaust emissions with the D-Jetronic — the first electronically controlled gasoline-injection system. The D-Jetronic helped newly registered vehicle types meet the requirements for lower pollutant emissions. Not only did this technology reach the goal of lowering emissions, but it also had the handy side effect of reducing both fuel consumption and spending. Further development of injection systems continued in the same vein, enabling ever greater economy in vehicle engines. The new injectors combined with a three-way catalytic converter and the lambda probe developed by Bosch (1976) to improve the combustion process and reduce exhaust gases by as much as 90 percent.

Since the second half of the 1960s, however, Bosch has also been researching alternatives to the internal-combustion engine as a powertrain. In the 1970s, Bosch showcased electric prototypes, as well as hybrid prototypes, which combined electric motors with internal-combustion engines.

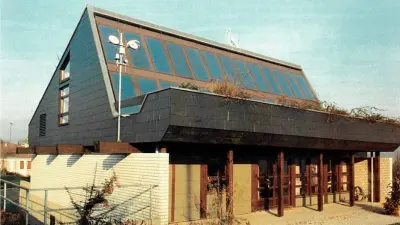

No less pioneering was the Junkers Tritherm experimental house completed by the thermotechnology division in 1976. The single-family home was heated by three sources: solar energy, outside air, and gas. It provided engineers with important insight into the optimum interaction between the solar panels, heat storage tanks, and heat pumps on the one hand, and the gas-fired heating system on the other. Under optimum conditions, the design reduced the amount of energy needed from fossil sources by 90 percent. Far removed from the high figures achieved in experiments like these, the Bosch developers of washing machines, refrigerators, and heaters were hard at work chipping away at water, electricity, and gas consumption in mass-produced items. Their efforts have really added up over time; for example, Bosch refrigeration devices now use as much as 80 percent less energy than in 1990.

Taking a stand

In 1996, the board of management formulated its ten environmental protection guidelines, which raised environmental protection to the status of a corporate principle as a third and equal goal alongside product quality and economic efficiency. By publishing its first environmental report in 1998, Bosch provided a complete overview of its environmental protection activities for the first time, from development and production through to the end of the products’ life cycle. The reports, which have been published regularly since then, make one thing in particular clear: constant work is involved.

Acting consistently

With more than 400 locations worldwide, Bosch has been carbon-neutral as a whole since 2020 in terms of Scope 1 and 2 emissions (direct emissions from the company and indirect emissions from purchased energy). Carbon neutrality was achieved by applying four levers: greater energy efficiency, in-house generation of energy from renewable sources, purchasing electricity from renewable sources, and — as a last resort — offsetting carbon emissions. As a result, Bosch offset remaining emissions of 0.7 million metric tons of CO₂ through carbon credits in 2022.

However, the company’s commitment to climate action is far from over. The journey continues. By 2030, Bosch plans to continuously enhance its climate neutrality measures and improve its Scope 3 carbon footprint, which covers the entire value chain through to the finished product and its use phase. The goal is a 15-percent reduction compared to the base year (2018).

Bosch is also making efforts to become more sustainable beyond climate action. That means making supply chains sustainable, strengthening circularity, and using resources efficiently.

Authors: Bettina Simon / Dietrich Kuhlgatz