Taking action for the climate

How Bosch brings its worldwide carbon footprint to zero

From 2020, Bosch will be completely carbon neutral. The more than 400 Bosch locations worldwide — from development through production to administration — will no longer leave a carbon footprint. In the year 2018, Bosch consumed around 7.8 terawatt hours of energy worldwide. It is not possible to reduce this consumption immediately and radically. However, the corresponding carbon dioxide emissions can be completely neutralized — around 3.3 million tons in 2018 throughout the company. To achieve this goal, Bosch has been relying on various ways of reducing carbon dioxide emissions for several years. Here some highlights.

Blaichach, Germany — electricity from the stream

Using the power of water has a long tradition at the location in Blaichach. The more than 100-year-old plant dating from 1907 was taken over by Bosch in 1960 and was extensively modernized and expanded in 2012 due to its great potential. Previously, only a maximum amount of water of 2.4 m³ per second could be processed, which meant that the water supply could not be fully utilized — especially during the snowmelt. The maximum annual energy production at this time was 9,000 MWh. The refurbishment included the installation of larger penstocks, a new power plant building and more powerful turbines. In 2018, the hydropower plant generated 12,200 MWh of renewable electricity and was thus able to cover around 45 percent of the total electricity demand at the site through its own generation.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

Rodez, France — sustainable heating

Reduce the site’s carbon footprint — that was what the team at Rodez in France set out to do when it started making plans as far back as 2009. The location now has a biomass heating plant, up and running since 2013. It burns wood chips obtained from local certified sustainable forestry resources. Rodez uses its power to heat water and generate process heat. On average, the wood chip-fired plant covers 90 percent of the location’s heating requirements. It consumes some 6,600 metric tons of wood chips a year. Burning this biomass releases no more carbon than the trees had taken from the atmosphere. The factory has reduced its yearly emissions by around 600 tons.

Juarez, Mexico — renewables as the main source of power

Mexico has revamped its energy policy. An energy reform launched there calls for the country to source 35 percent of the electricity from non-fossil fuels by 2024. With many hours of sunshine annually and high-wind regions, Mexico’s geography and climate would certainly support that goal, providing a solid foundation for change alongside committed support from government and business. Bosch is part of this movement, and has already set a high standard: power sourced exclusively from the Dominica wind farm in the state of San Luis Potosí covers more than 80 percent of the energy requirements of all Bosch locations in Mexico. Bosch Mexico was able to save 56,000 metric tons of CO₂ in 2018 by switching to predominantly renewable energies.

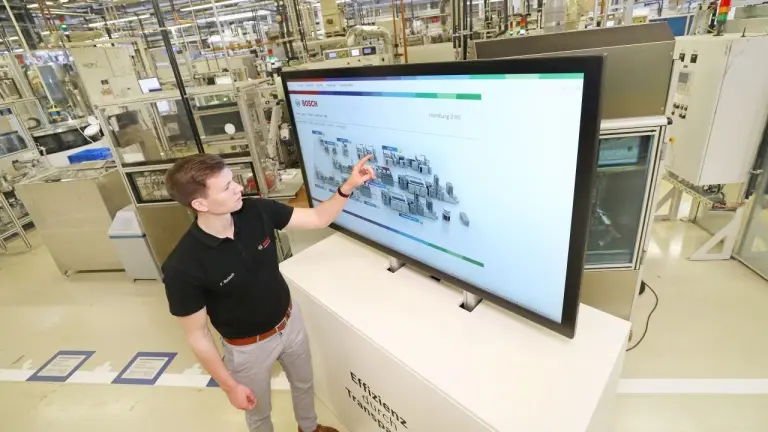

Homburg, Germany — crunching data to conserve energy

The Bosch location at Homburg, in the German state of Saarland, is edging ever closer to the vision of an energy efficient, self-learning plant. It has spared the world around 5,000 metric tons of carbon dioxide in the past two years and more than 23,000 tons since 2007. This approach pairs maximum transparency with technical innovation. An energy management platform developed by Bosch uses data from the machinery collected at some 10,000 measuring points. Associates can track, control, and optimize each individual machine’s power consumption. Technical solutions include ventilation of manufacturing shops on an as-required basis, utilization of waste heat from various machining processes, and smart consumption management for machinery.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.