Circular economy: Bosch Research optimizes product life cycles

By analyzing product life cycles, improving resource and energy efficiency and recycling materials intelligently, Bosch Research allows more sustainable products.

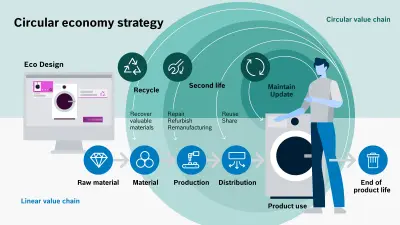

Mankind is facing a fundamental problem: the earth does not have enough resources to satisfy current levels of demand in the long term. At the same time, the environment is suffering as a result of the emissions produced when new products are manufactured and used. Bosch therefore strives to use resources sustainably and has set itself the goal of strengthening the circular economy while developing more and more products that have more than just one life. Bosch Research is researching the concept of the circular economy and its underlying methods. We are thus helping Bosch to develop and manufacture products even more efficiently in cycles in its various business areas. The researchers at Bosch Research are also working on technological solutions which safeguard sustainable material flows and increase resource efficiency.

Life cycle assessment: data analyses for sustainable product development

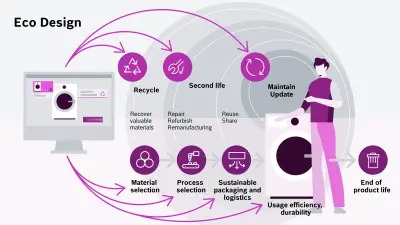

If a resource-efficient circular economy of Bosch products is to succeed, the entire product life cycle must be considered. A key part of our research work therefore lies in developing methods which make the environmental impact of Bosch products transparent. Life cycle assessment (LCA) can be used to depict complete product life cycles and identify potential for ecological improvements. These can be individual materials, components or production steps. With these methods, Bosch Research can find out how sustainable a product will be while it is still being developed. The simulations obtained show how products can be made more sustainable by changing the materials, production environment or the product design. Tailored LCA approaches thus complement existing methods in product development at Bosch. The findings gained from applying these methods enable us to identify the most critical aspects in the life cycle of our products and make specific changes during the design phase. This sustainable and futuristic approach is known as eco design.

Circular economy and eco design go hand in hand

Eco design is an important part of the circular economy and includes all design decisions during product development which make the result more sustainable. Sustainability criteria are taken into account when selecting materials, planning production processes and in logistics. Various design principles are also used to extend a product’s service life, to allow more intensive use or even to give the product a second life. The aim is to use fewer resources during the product life cycle. At the same time, a long product life is not necessarily better than a shorter one: if for example the energy efficiency of a new product generation is clearly superior to that of the older one, it may be advantageous from a sustainability point of view to replace a device earlier and recycle the old one. Our product developers use the LCA methodology to find out exactly when this point is reached.

There are various forms of reuse and recycling as part of the circular economy, from maintenance, updating, repairs and reuse to overhauls, reworking or redesigns. For example, used parts can be used for products instead of brand new ones, thus giving them a “second life”. In the context of the circular economy, another aim is to recover valuable materials at the end of the product's life and to use them for the manufacture of new products (recycling).

Three approaches for the circular economy

1. Maintain and update

A first step when it comes to extending the service life of products involves maintaining and caring for them or updating them via software updates for example to ensure they can be used for a long time. Regular, proper maintenance, for example changing the oil in an engine or maintaining heating systems, can prevent products breaking down prematurely. If possible, they should also be updated to maintain their functionality and performance or even improve them.

2. Second life

The term “second life” means extending the life of products by reusing them in the same or a different application, repairing or reconditioning them or using individual components from old devices a second time.

All products break down at some point or the material they are made from wears out. Repairing them extends their service life. This means that defective parts are repaired or replaced in order to get the product working again. Examples of this include the Bosch repair service or the Bosch Power Tools repairs factory in Willershausen.

In the circular economy, products should be designed so that they can be reused by someone else in other applications after their first life or shared. This allows them to be used more intensively. One example is the "We Wash" program from BSH Hausgeräte GmbH (BSH) for shared washing machines in residential buildings and the associated digital billing systems for shared laundry rooms.

If products which still work are overhauled and refurbished, they can be put back on the market later on. This extends their service life. Product quality is always checked in the process. In contrast to “remanufacturing”, this process typically does not achieve or guarantee the same quality standards.

During remanufacturing, a product’s components are removed and checked. Damaged parts are repaired or replaced and the product is then put together again. The aim is to come up with a recycled product which meets the same quality standards as a new product. One example of this is the Bosch eXchange program in the automotive sector, which gives Bosch workshops the option of sourcing reconditioned parts from certified plants for repair work.

3. Recycle

Product recycling, as opposed to second-life approaches, involves recovering the recyclable materials used. The original product is destroyed in the process and the materials are recovered, for example by melting them down. The old material thus becomes a secondary raw material from which new products can be manufactured.

For these three approaches to become reality, products must also be designed for them — with a focus on repairability, reuse, refurbishment, remanufacturing and recycling. At Bosch Research, we develop training courses for Bosch's business units in order to raise awareness of these approaches among employees and thus incorporate eco design into the product development process.

New materials from waste

Selecting the right materials when developing new products is an important part of eco design. At Bosch Research, we are constantly looking for ways to increase the proportion of sustainable materials in our products. For example, upcycling is used to create new products from supposed waste. However, it has always been difficult to manufacture sophisticated industrial products that can withstand high mechanical loads and long service lives from recycled material. As part of the “Sustainable plastics” project, a team of experts at Bosch Research is trying to achieve exactly that. The main focus is on finding the right material. Old car batteries have already been used successfully to produce housings for ultrasonic sensors that are used in vehicle parking pilots.

The circular economy needs recycling solutions

Material recycling is an important option for the circular economy where second-life approaches cannot be implemented or do not make sense. In various projects, the researchers at Bosch Research are developing concepts to improve the recycling of materials. One approach which is being followed at the moment is urban mining — for example the recovery of precious metals from defective electrical appliances and electronic components as opposed to obtaining them from natural sources such as ores.

If urban mining is to be a success, it is important to be able to dismantle appliances cost-effectively and to develop suitable dismantling strategies. The aim is to recover as many valuable material resources as possible with minimal energy use. This way, the cycle of materials can be closed and a more sustainable use of resources is made possible.