The Bosch hammer drill

Breakthrough with a decades-long impact

From its beginnings in the 1930s to the present day, the Bosch hammer drill has shaped the world of construction and has made its way onto building sites all over the world, soon establishing itself as an indispensable tool in the construction industry. Bosch then went on to introduce the first cordless hammer drill some 40 years ago.

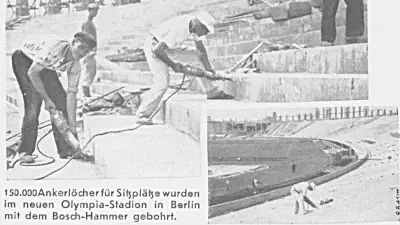

A rhythmic roar breaks through the dusty silence on the construction site of the future Olympic park in Berlin. The Bosch hammer drill is beginning its work. The worker’s hands are firmly clasped around the handle of the hammer drill as he controls the tool with precision. Drilling in hard materials always used to be a tough job, often leading to poor results. But now clean, round holes are produced — and in an incredibly short time too.

In 1925, the crisis in the German automotive industry brought severe sales losses to Bosch. Later, Black Friday — the stock market crash on October 25, 1929 — shook the global economy to its very core. Bosch, known until then for its ignition systems and automotive electrics, decided to shore itself up with additional business areas. During this time of upheaval, Bosch introduced a power tool that would become indispensable in workshops and on construction sites for decades to come.

The Bosch engineers were now faced with a mammoth task: to develop a construction hammer drill with the strength and durability to withstand rough building work. This wasn’t just any hammer drill, either. It was a tool that emerged from a collaboration with a Swedish company that had come up with an impact mechanism combining hammer and rotary motion. The impact mechanism penetrated materials faster and with less force, allowing more precise and cleaner drill holes compared to pure percussion drills or rotary drills. Bosch acquired the patent, and, under the leadership of the experienced engineer Ottmar Baur, the hammer department began its work. The Bosch hammer drill made its first public appearance at the Leipzig Trade Fair in 1932. The groundwork had been laid for a truly breakthrough tool.

In 1934, the Bosch hammer drill was launched on the market after a number of design improvements. One of its first major projects was reinforcing the railings along the Weinsteige, a spectacular series of outdoor stairs scaling the cliffs on the southern edge of Stuttgart. The Bosch hammer drill made it possible to drill 1,200 anchor holes in less than 400 hours. Normally, a task of that magnitude would normally have required 1,700 hours of manual labor.

If the hammer drill was just a drill, it would naturally have been worth considering whether the hefty 600-reichsmark price tag was a good investment. But the Bosch hammer drill was also a chisel drill, caulking hammer, bush hammer, compacting hammer, and vibrating hammer all rolled into one. Not only that, it was also an electric hammer that you could simply connect to the light circuit! The Bosch hammer drill also proved its worth during the construction of the Olympic Stadium in Berlin, helping to ensure that the work was completed within the tight schedule.

The ability to drill precise and clean holes improved the quality of the installation work and the accuracy of anchors and fixings. As a durable and reliable tool, it also reduced the physical strain on the workers. The Bosch hammer drill saved time and money, and became a valued assistant to builders and developers alike.

The principle of the impact hammer drill was followed in the 1960s by the electro-pneumatic system, in which electrical energy was converted into mechanical energy using compressed air. Precise, powerful, and with minimal energy loss, this enabled faster drilling with less wear on the tool.

Over the decades, the original 7.5 kg hammers drills became increasingly lighter. Bosch unveiled the world’s lightest electro-pneumatic hammer drill in 1981. The cordless hammer drill was presented all the way back in 1984, followed twenty years later by the world’s first hammer drill with lithium-ion battery technology. Today, innovative sensor technology recognizes the impact rate required by the hammer drill for its task and prevents a kickback when the drill hits the wall. The cordless hammer is just as powerful as a corded tool, making it even more versatile.

Author: Angelika Merkle