New dimensions for development and manufacturing

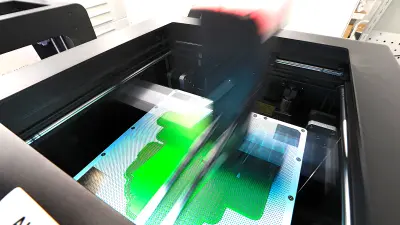

Impressions of the Bosch center of competence for 3D printing

The advantages of 3D printing are the new freedom it brings to geometrical design, as well as a high degree of customization. Thanks to the center of competence for 3D printing, engineering and manufacturing associates are already making use of these additional benefits.

“Developments are racing along like an express train,” says Jan Tremel, the head of the center of competence for 3D printing, which belongs to the Gasoline Systems (GS) and Diesel Systems (DS) divisions. “That’s why it’s so important for us to be making use of this technology now within our company, and giving people the skills they need to work with it.”

The center of competence (CoC) is taking a two-pronged approach. The developer training center (DTC) at the Schwieberdingen location gets developers from the company's various divisions up to speed with the technology. While the focus is on GS and DS, the aim is to show all divisions how 3D printing can be used to construct prototypes. Workshops give developers the opportunity to see what is possible. To this end, ten industrial 3D printers have been available at the Schwieberdingen location since March 2016.

“This centralized CoC initiative is much more efficient than having individual departments explore the possibilities of 3D printing for themselves,” Tremel says. The majority of the printers in Schwieberdingen print plastic, and can be used to produce presentation models or functional prototypes on the basis of ideas at a very early stage of development. The geometric freedom this printing process offers is much greater than with conventional manufacturing methods such as turning or milling.

“Now, in just a single day, our developers can print five variants of an injection valve, refer directly to the models in discussions with colleagues, and evaluate the merits of the different variants.”

The CoC’s other focus is on manufacturing. Since 2017, the 3DP manufacturing and processing center (MPC) at the Nuremberg plant has been concerned with manufacturing components and garnering production experience. For example, a high-pressure pump is currently being developed for the injection system of a Formula 1 engine. This kind of extremely customized component, where weight is minimized and performance is crucial, and which will be produced in extremely low numbers, is one of the ways in which 3D printing will find its way into mainstream production. It means a product can be tested in the market without first having to invest heavily in a production line.

“Increasing market volatility, coupled with growing demand for several different variants, is a great opportunity for 3D printing,” Tremel says. “It enables us to supply our customers with new products in an extremely short time and in completely new fields.” Tremel is certain that “there will be fewer and fewer components that stay unchanged over decades and identical across markets worldwide. 3D printing lets us customize products and adapt them even better to our customers’ requirements.”

Summary

In Schwieberdingen, Bosch is training engineers from all its divisions to exploit the possibilities offered by 3D printing. The center of competence’s work also focuses on the company’s manufacturing operations.