History of Bosch Thermotechnology

Heated for life

Throughout his life, Robert Bosch was enthusiastic about technical breakthroughs and innovations. Unsurprisingly, he equipped his private home with a modern central heating system when it was built. That was around 1910. More than 20 years later, Bosch started making heating systems and hot water appliances. In doing so, the company laid the foundation for today’s Bosch Home Comfort Group division, which offers innovative and sustainable solutions for heating, cooling, and well-being in buildings.

The start of Bosch heating and hot-water technology

In 1926, Alfred Meyer, the head of Bosch’s patent department, was given the special task of finding new fields of activity for the company. Times were tough in the automotive industry, and Bosch wanted to diversify its business, which was focused solely on automotive technology. With gas-fired products growing more and more popular, Meyer thought developing a safety pilot for gas burners would be a promising venture. His idea was a response to risk factors that had been given too little attention so far: at the time, unused gas could still escape even after the flame went out, creating a substantial danger of explosion and gas poisoning.

An invention from the United States that was capable of at least preventing gas leaks after the flame was extinguished had already been engineered to address the problem. However, this safety gas switch took several minutes to become active, meaning it was still impossible to reliably prevent explosions. Meyer had the ambitious aim of speeding up the process by leaps and bounds. The breakthrough came in 1929, when Bosch developed a safety gas switch that was capable of activating itself in mere seconds. Standing between it and the market, though, was a wide-ranging patent held by the Dessau-based heating and hot-water appliance company Junkers & Co. Initial talks proved slow and difficult. Yet before an agreement could be reached and larger-scale marketing activities initiated, the nascent Great Depression changed the situation drastically. With his entire group of companies in dire financial straits, Hugo Junkers decided in 1932 to sell his natural-gas appliance division to Bosch.

The endurance test

Stability guaranteed

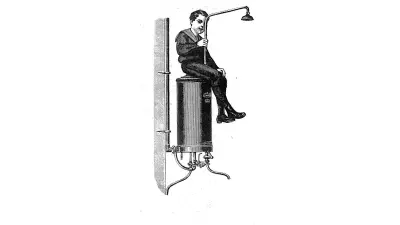

Junkers made the first wall-mounted natural gas-fired water heater in 1896. To save space and money, it mounted the appliance over the gas pipes on the wall. Hugo Junkers used an image of his nephew sitting on the natural gas-fired water heater to advertise the stability of the design.

Cozy heat and comfort in the bathroom

With its cost- and energy-efficient gas-fired bath water heaters, Junkers had made an important contribution to hygiene. By the mid-1950s, though, a new trend was on the horizon. People were demanding higher living standards, which meant having the comfort of both heating and hot water in their homes. Junkers met those demands with products such as the Junkers Gasiator, a highly economical gas-fired radiator that was easy to use and required no maintenance, among other advantages. Just as importantly, its flame failure device provided maximum safety. The persistence displayed by Meyer, who had long since retired, had indeed paid off.

A comfy, cozy bathroom — a wish Junkers boilers made come true.

Sustainability and alternative forms of energy

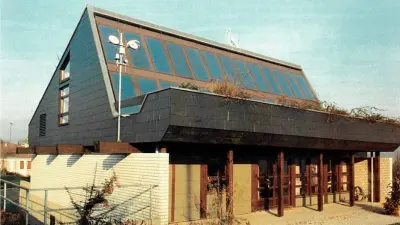

In the 1970s, the political and economic situation changed dramatically yet again — a fact that had become apparent to every household by the start of the oil crisis. For the first time, alternative forms of energy and the conservation of resources were important topics for the general public. Energy efficiency had always been an aim for the heating systems industry, and the new situation provided an additional source of motivation. In 1975, Junkers unveiled the prototype of a heat pump that used groundwater as a heat source. In summer, it was used to heat water, with the heat also being used to warm indoor spaces in winter. Researchers at Junkers took things one giant step further with the Tritherm house. Constructed in 1976, the experimental house was equipped with a heat pump, 25 solar collectors and a gas-fired central heating system as a reserve for particularly cold winter days. The house provided engineers with vital insights into the optimum use of different heat sources and how to link them up.

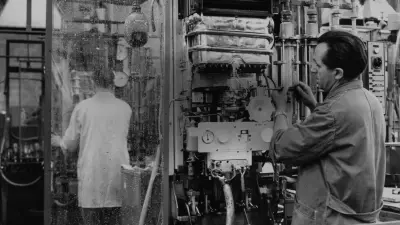

Buderus, which has been part of Bosch since 2004, also used the 1970s to take a significant technological leap forward. In 1977, the Ecomatic low-temperature boiler hit the market. The innovative new approach made it possible to link the boiler’s operating temperature to the outdoor temperature, enabling energy savings of up to 30 Prozent and setting the standard for an entire industry. In addition to conserving resources, Buderus also focused its attention on alternative forms of energy and presented heat pumps and solar collectors at international trade shows.

Heat Pump Hybrid Solutions — The next step in the energy transition

Today, heat pumps and solar collectors play an essential role in new buildings. As a climate-friendly alternative for existing buildings, Bosch Home Comfort offers heat pump hybrid solutions. With these, users benefit from the optimized efficiency of a gas condensing boiler and the regenerative energy use of a heat pump in one system. The heat pump regularly covers up to 80 percent of the heat requirement using renewable energy. If the energy potential of the heat pump is exhausted, the gas condensing component provides the required heating power, for example in the event of power or flow temperature peaks. The integrated hybrid manager acts as a smart energy manager, selecting the optimum energy source depending on the energy demand and ensuring the highest possible efficiency level of the hybrid system. In this way, the hybrid system ensures economical consumption despite high performance. The energy savings are also accompanied by reduced CO₂ emissions.

Author: Carmen Senger