With a new drive into the electricity age

Bosch Research conducts research into innovative electric drives, steering systems, braking systems, and thermal management for the e-mobility of the future.

The shift to electromobility is in full swing around the world: in the European Union, for example, newly registered cars and light trucks will not be allowed to emit CO₂ after 2035. Vehicle manufacturers will therefore have to convert their model range to electrified mobility by then. Bosch is paving the way with components, products and system solutions. Bosch Research is putting in place the technological foundations for the transformation to electrified mobility — and for all vehicle types: from e-bikes, motorcycles and cars to trucks and all off-road vehicles such as excavators. We develop technologies for all stages of the electric vehicle value chain, i.e., semiconductors and components such as power electronics, drives and complete systems. Bosch Research places particular emphasis on sustainability. When developing technologies for electrified mobility, energy efficiency and recycling are of great importance. For example, we are researching new materials with a smaller CO₂ footprint that can also be used to reduce the overall weight of vehicles.

All new: electric drives and braking and steering systems for the electric vehicle of the future

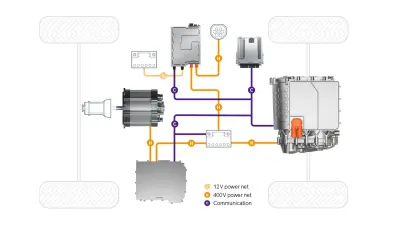

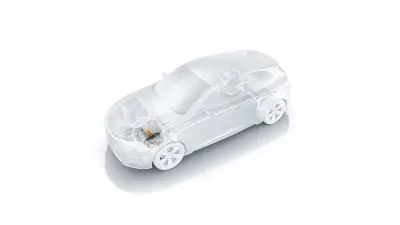

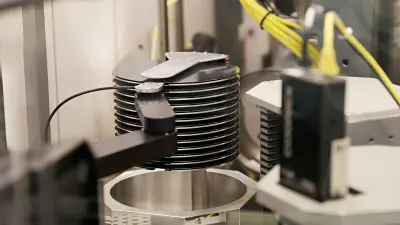

One key area of Bosch Research’s electrified mobility work is electric drives. With the Bosch eAxle, for example, we are designing an innovative, highly efficient overall system for electric vehicles. One of our goals is to make the individual components — from the electric motor to the power electronics and transmission — as sustainable as possible. For example, by using alternative, recyclable materials. We address central issues such as: is copper the electrical conductor of the future? Or: how can magnets made from rare earth metals be replaced with more sustainable, more easily available materials? To answer these questions, we draw on our many years of expertise in material simulation at Bosch Research. We combine this domain knowledge with the latest artificial intelligence (AI) methods and also carry out research into the use of quantum computers for the material simulation of the future.

But electrified mobility is not the same as electric drives. New conditions such as globally reduced maximum speeds, connected and autonomous driving functions and greater customer demands in terms of freedom from maintenance are placing new demands on electrified mobility. However, they also offer great potential for innovation.

In addition to optimizing the electric drive itself, there are implications for the entire vehicle: the basic functions of driving, braking, and steering are converging. For example, the electric axle of the future will take over large parts of the braking function, and hydraulic braking and steering systems can be replaced by “dry by-wire products,” i.e., systems that are operated purely electrically via wires. Bosch researchers are therefore working on new concepts for braking and steering systems that are tailored precisely to the new requirements of electric vehicles.

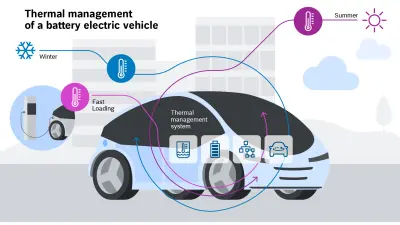

Always at the right temperature: Intelligent thermal management for the electric vehicle

Thermal management is another important area of research in electrified mobility. At Bosch Research, we are developing components and solutions that allow the vehicle interior to be brought to comfortable temperatures with maximum efficiency — on hot summer days as well as cold winter days. We are thus playing a key role in increasing the vehicles’ range.

Optimum charging too requires correct temperature control for the battery. The aim is to charge the battery as quickly and efficiently as possible, maximizing its service life in the process. The overall goal of electrified mobility is to optimize vehicle energy management, i.e., the optimum use of electrical and thermal energy. This is systematically pre-developed and realized in components and systems.

In the right place at the right time: Intelligent energy management

Bosch Research is also looking at charging technologies for vehicles, buildings and in the charging infrastructure. We are developing smart charging solutions that can be used to link charging stations and decentralized photovoltaic systems and to optimize the utilization of grid connections. The energy management systems that Bosch Research is working on also optimize bidirectional charging and ensure that the vehicle batteries will be able to feed stored energy into the electricity grid if necessary. We are developing hardware as well as suitable software solutions. Automotive manufacturers, customers, fleet operators and households all benefit from these innovations.

In addition to research into fully electric vehicles powered by batteries, we are also conducting research into fuel cells as an alternative energy storage system for mobile applications.

E-mobility needs highly efficient power semiconductors

All electrified components and systems are driven by power semiconductors. The ever increasing demand for more power semiconductors in the future and the shortage of supply is a major challenge not only for the automotive industry but also for industrial electric drives, household appliances, power tools and many other products.

Bosch has decades of experience when it comes to researching, developing and producing semiconductor components. The two big semiconductor production sites in Reutlingen and Dresden, Germany, are an extremely important part of the global supply chain. That is why Bosch Research has been working for many years on the most advanced power semiconductors (so-called wide-bandgap semiconductors), for example those based on silicon carbide or gallium nitride, which will make all electrified products and systems more efficient and sustainable.

Mastering complexity

Electrified mobility requires bringing together previously separate systems and technologies — such as the power supply, battery technology, charging infrastructure and energy management. As the role of software increases and the requirements become more demanding, the individual components must be connected. These requirements include longer operating times and growing safety requirements for electric cars. Bosch Research addresses these needs by developing and using the latest model-based system engineering (MBSE) methods and tools coupled with advanced multi-objective optimization methods to meet all key design requirements. Ultimately, this makes processes more sustainable and efficient since simulations and a better understanding of materials and systems make it possible to dispense with complete physical sampling phases during development. In addition, Bosch Research is exploring the use of AI in the development, testing, production and lifetime monitoring of all components and systems in the vehicle using digital twins.