With virtual development to more sustainability and efficiency

Virtual prototyping enables groundbreaking developments — Bosch Research pursues a wide variety of interdisciplinary research approaches in the digital development of products and at the same time establishes an international research network with institutions around the world.

Even in the constantly and ever more rapidly changing world of technology, development and production, there are core concerns that have not changed over the centuries. Developing products and solutions more quickly and more cost-effectively has always been one of them. In the past, processes and products were usually tinkered with and tested based on experience, in a resource-intensive manner and over long periods of time. Today, however, things move much faster. Digitalization and connectivity make it possible: What used to take six to seven years to develop is now usually ready in less than three years — and the pace is still increasing. The aim of our research is to reduce the development time for a product or technical solution by a further 30–50 percent.

Develop, test and publish in the digital space

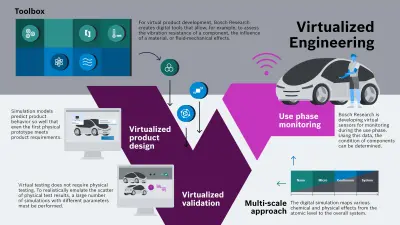

Virtualized engineering, the development of technical systems, parts and components based on three-dimensional models in digital, virtual space, helps to significantly reduce the overall development time of products and services. Nowadays, virtually all steps in product development can be digitalized, at least to a certain extent. Products and solutions can be tested, adapted and improved while they are still being developed. During the development process, virtual development, i.e., development in virtual space, is the top priority. So-called digital twins depict entire products in digital form and allow the coordinated development and simultaneous testing of multiple development steps that, in certain cases, could only be carried out sequentially. This is followed by virtual testing, the test phase and a targeted run-through of the entire system under real conditions — once again digitally. Successful completion culminates in the virtual release, digital release or rollout of the digital image of a product.

The key question when applying virtualized engineering processes to the development of products is often “How does a component behave under what conditions?” The physical testing of a component in the sample phase has always been the most costly and time-consuming part of development. In simulation, however, numerical models have often proven too inaccurate to be able to draw conclusions. Or the opposite extreme resulted when a numerical model was created: an excessively long simulation time, as a result of which the desired cost reduction cannot be achieved.

Digital means faster and more sustainable

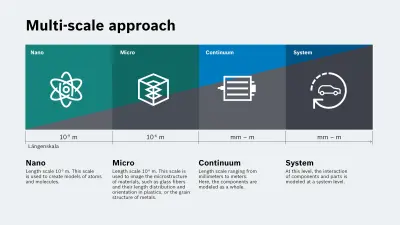

At Bosch Research, we are always looking for and developing new methods, concepts, and ways to further shorten the time from the idea to a marketable product and to further increase efficiency and sustainability. When testing new processes and solutions, we work closely with the other Bosch divisions. This close partnership allows great progress when developing new technologies. It is now possible to analyze and break down materials in more detail – even down to their atomic level. This saves a great deal of time during subsequent work steps, for example scaling. Another advantage of digital material analysis is the fact that product properties can be predicted in advance on the basis of existing data. All these methods which are now widely used come under the heading of virtualized engineering — a field in which Bosch has been carrying out intensive research and development work for a long time.

Toolbox

The behavior of metallic components is modeled in order to avoid fractures and deformations. For this reason, the influence of manufacturing processes such as heat treatment and material properties on the microstructure is simulated.

The influence of raw material, geometry and manufacturing process on component behavior must also be simulated for plastic components.

Bosch Research models the behavior of components in terms of wear and friction.

The influence of environmental conditions such as temperature on the corrosion of a component is mapped by our Bosch Research experts.

This subsection determines the vibration resistance of a component. This includes the influence of vibration loads as a function of material, geometry and manufacturing process on the lifetime of components. Furthermore, the transmission behavior of vibrations in the system (several components) is modeled.

Bosch Research models physical and chemical mechanisms at the atomic and molecular level. This allows, for example, the selection of materials with regard to their conductivity. We are developing algorithms to immensely accelerate computing speed at this scale using quantum computing.

With this tool, Bosch Research can calculate the extent to which operating parameters, materials and geometry influence the performance and service life of a fuel cell.

This domain deals with the modeling of fluid mechanical design challenges. The focus is on the coupling with other physical effects (multiphysics), geometry optimization and computational speed.

With AI to faster computers and computing results

Bosch Research carries out research on the macro, micro and nano scales on which the interrelationships with the technology available today can be adequately represented physically and yet still be calculated. Because the insufficient computing capacity of computers was often a problem in this area of research in the past, Bosch Research has found other ways to get around the problem. We combine our research with artificial intelligence (AI) to speed up computing times and take advantage of specific effects using AI and its data-driven approaches. However, we are also working on improving technologies to speed up the computers available today. In summary, virtualized engineering as a research field covers the complete spectrum of modern digitalization and connectivity, from basic mathematical and physical methods to the application of artificial intelligence and even quantum computing.

Bosch Research leverages the data potential of a global corporation

The advantages of virtualization are that models and simulations can be greatly improved by increasing computing speeds. Carrying out development work in virtual space saves a lot of time and money while protecting the environment. The input obtained from virtual simulations is taken into account in all developments at Bosch.

Once again, Bosch Research benefits from being part of a global corporation, where all the data available in the company from physical and software-driven areas can be combined and used. Areas of application for this enormous input are all hardware components produced by Bosch: From drills and eAxles to medical technology. Wherever possible, we use commercial software to apply our research as efficiently as possible. Open source and commercial software are used via plug-ins or add-ons. A plug-in is a software extension, but one that functions even without the main program. An add-on also extends an item of software but it cannot run on its own and is therefore beneficial only in conjunction with the main program. Open source software development plays a key role in the virtualization of development both in internal and external projects. Bosch Research uses open source programs in the same way as it does commercial tools. One example is OpenFoam which is used for fluid calculations. However, Bosch also uses its own open source programs.

Virtual development — with interfaces to the world of science

In the field of virtual prototyping, Bosch Research collaborates with internationally renowned universities and institutes in Germany and other European countries. In the fields of atomistics and molecular dynamics for example, Bosch collaborates with the Massachusetts Institute of Technology (MIT) and the Karlsruhe Institute of Technology (KIT). In the area of microstructure simulation, it works with the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg. Collaborations of this type give us access to knowledge which is not yet available outside Bosch Research. Colleagues who join Bosch Research from universities or research institutions often bring with them the latest results from basic research as well as interdisciplinary approaches to our research work. Approaches and methods of classical engineering sciences are combined not only with physics and mathematics but also with AI and software engineering. The interdisciplinary approach to research thus reflects the numerous overlaps and interconnections of virtual engineering as a research field.